Before 2015, every time a rocket launched into space, it was destroyed. The first stage, the most expensive part, fell into the ocean and was lost forever. That changed on December 21, 2015, when SpaceX landed a Falcon 9 first stage back on solid ground - the first time an orbital rocket ever did it. That single landing didn’t just make headlines. It started a revolution in how we get to space.

Why Reusability Changes Everything

Think of a rocket like a commercial airplane. A Boeing 737 costs more to build than a Falcon 9 rocket. But airlines don’t throw away planes after one flight. They fly them hundreds of times a year. That’s how they keep ticket prices low. Reusable rockets work the same way. Instead of spending billions on new rockets for every launch, you build one and use it over and over.Before reusable rockets, launching a kilogram of payload to low Earth orbit cost between $10,000 and $20,000. Today, thanks to Falcon 9’s reusability, that cost has dropped to around $2,700 per kilogram. That’s an 80% drop in just a decade. The reason? Amortization. When you fly a booster 10 times, you spread the cost of building it across 10 missions. Fly it 15 times? The cost per launch drops even further.

How Do Rockets Land and Fly Again?

It’s not magic. It’s engineering. Falcon 9’s first stage uses four key systems to return safely:- Propulsive landing: After separating from the upper stage, the booster fires its Merlin engines to slow down and control its descent.

- Grid fins: These titanium fins steer the rocket through the atmosphere, adjusting its path like wings.

- Landing legs: Deployed just before touchdown, they absorb the final impact.

- PICA-X heat shield: This special material, developed by SpaceX, withstands temperatures over 1,650°C during re-entry - and survives it 10 to 15 times.

After landing, the booster is towed to a refurbishment facility. Technicians inspect every component. Engines are tested. Heat shield tiles are checked. Some parts, like turbopumps, need replacement after 5-7 flights due to metal fatigue. But most of the rocket - the tanks, avionics, and structure - stays intact.

Early reusable concepts took months to refurbish. SpaceX cut that down dramatically. By 2022, booster B1062 flew again just 96 days after its previous mission. That’s faster than most commercial jets take for major maintenance.

Launch Frequency: From 20 to 60+ Per Year

Before reusable rockets, no company had ever launched more than 20 times in a single year. Why? Building a new rocket for every launch is too slow and too expensive.SpaceX broke that ceiling in 2022 with 61 launches - 87% of them using previously flown boosters. In 2023, they hit 97 launches. That’s more than one launch every 3.5 days. That kind of cadence was impossible with expendable rockets.

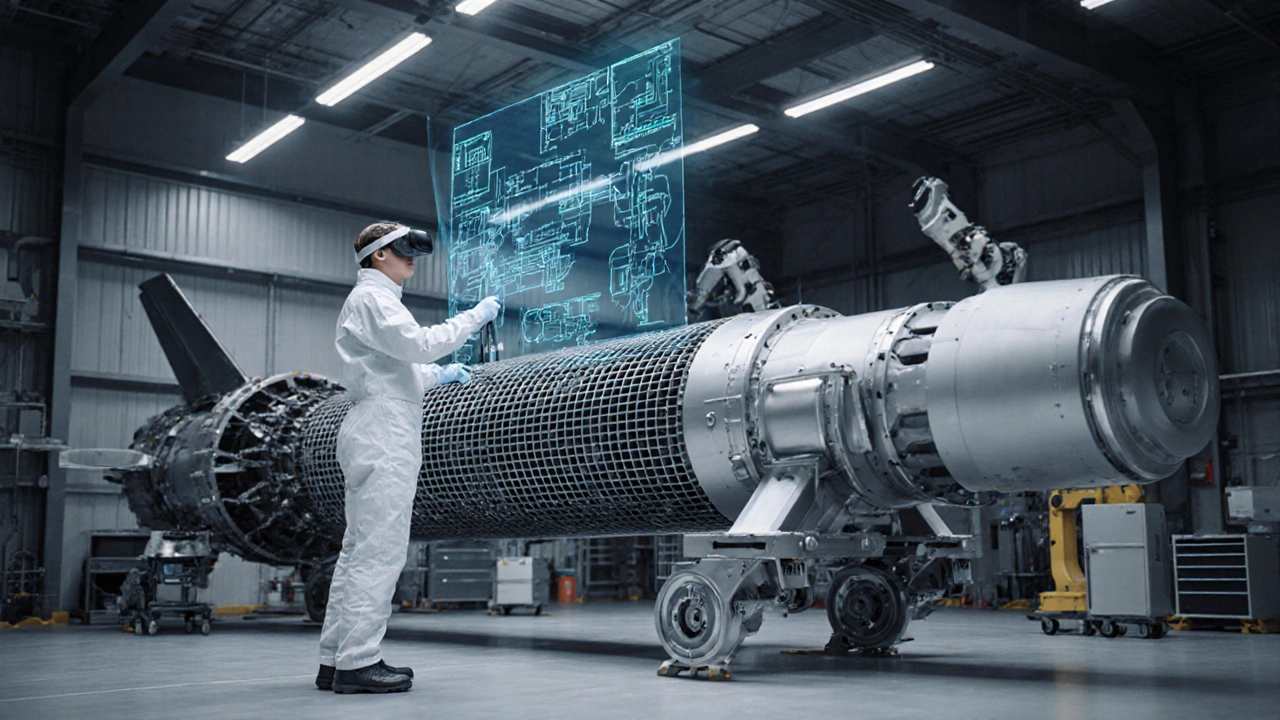

Compare that to Rocket Lab’s Electron. It recovers its first stage, but the process takes 6-8 weeks. That limits them to 10-12 launches a year. SpaceX’s advantage isn’t just reusability - it’s rapid turnaround. They’ve built automated inspection lines, trained teams to work in parallel, and use augmented reality (AR) to guide technicians through repairs. Their goal? A 24-hour turnaround. Elon Musk has said they’re testing systems that could one day relaunch a booster within hours.

Who’s Winning the Race?

SpaceX is the leader - but they’re not alone.- Blue Origin is developing New Glenn, which will reuse its first stage. Their New Shepard suborbital rocket has already flown 26 missions with an average 28-day turnaround.

- Stoke Space is designing a fully reusable two-stage rocket with no stage separation. Their prototype targets a 24-hour turnaround by eliminating the complexity of separating and recovering multiple parts.

- NASA and international partners are testing the CALLISTO demonstrator, which achieved a 45-day turnaround in 2022 - but found that inspecting the heat shield alone took 14 days, making it the biggest bottleneck.

The difference between these companies and SpaceX comes down to scale and integration. SpaceX doesn’t just build rockets. They own the launch pads, the tracking systems, the manufacturing plants, and the refurbishment facilities. They control the entire pipeline. That’s why they can turn a booster around faster than anyone else.

Why This Matters Beyond Cost

Lower costs and higher launch frequency aren’t just good for business. They’re changing what’s possible in space.Starlink, SpaceX’s satellite internet network, needs about 40 satellites deployed every few weeks. Without reusable rockets, that would be impossible. Each launch costs less than $50 million. With expendable rockets, it would cost over $200 million. The entire constellation - over 6,000 satellites so far - exists because of reusability.

NASA has also benefited. In 2022, their Launch Services Program found that using Falcon 9 allowed them to fly 37% more science missions within the same budget. Missions to study asteroids, monitor climate change, and test new telescopes became feasible because they didn’t have to compete for expensive, rare launch slots.

The U.S. Space Force is now funding projects to achieve 24-hour turnaround for military resupply missions. Imagine sending replacement satellites, sensors, or supplies to orbit on demand - not months in advance. That’s the future they’re building.

What’s Holding Us Back?

Reusability isn’t perfect. There are real limits.First, inspection time. Even with automation, a basic turnaround still takes 20-30 days. The heat shield and engine components need careful checks. That’s the biggest bottleneck.

Second, regulation. The FAA requires 30-60 days between launches from the same site for safety reviews - regardless of whether the rocket is reusable. That’s a legal barrier, not a technical one.

Third, complacency. As reuse becomes normal, there’s a risk that inspections get rushed. The NASA Aerospace Safety Advisory Panel warned in 2023 that “normalized reuse” could lead to overlooked damage. They recommend mandatory third-party checks after 10 flights.

And then there’s the cost of development. SpaceX spent $1.2 billion on reusability R&D between 2010 and 2015. Most companies can’t afford that kind of upfront investment. That’s why SpaceX still dominates - they bet big when no one else would.

What’s Next? Starship and the 1,000-Launch Future

The next leap isn’t just about Falcon 9. It’s about Starship.Starship is designed to be fully reusable - both the booster and the spacecraft. It’s made of stainless steel, which is easier to repair than carbon fiber. It uses rapid propellant loading, so refueling takes minutes, not hours. SpaceX aims for 3-4 hour turnarounds between launches. They’re testing systems that could let a single Starship vehicle fly 100 times a year.

If they succeed, global launch frequency could jump from 186 in 2023 to over 1,000 by 2030. That’s not science fiction. Morgan Stanley projects the reusable launch market will grow from $5.2 billion to $24.7 billion in that same time.

Why? Because frequent, cheap launches unlock new industries: space manufacturing, orbital solar farms, lunar supply chains, and even space tourism. Reusable rockets aren’t just cheaper - they’re the foundation for a new space economy.

Final Thought: It’s Not About the Rocket - It’s About the Rhythm

The real breakthrough isn’t that rockets can land. It’s that they can fly again - and again - and again. We’re moving from a world where space access was rare and expensive to one where it’s routine and affordable. Like airplanes, like trains, like ships - space travel is becoming part of everyday infrastructure.The question isn’t whether reusable rockets will dominate. They already have. The question is: how fast can we make them fly again?

How many times can a Falcon 9 booster be reused?

Falcon 9 boosters have flown up to 15 missions with minimal component replacement. The engines, particularly the Merlin 1D, are designed to handle 20+ full-duration firings while maintaining over 95% performance. However, after 10-15 flights, major refurbishment is needed - especially for the heat shield and turbopumps, which degrade over time.

Why can’t all rockets be reused?

Early rockets weren’t built for reuse. They were designed to be lightweight and disposable, sacrificing durability for performance. Reusable rockets need stronger structures, heat shields, landing systems, and redundant controls - all of which add weight and complexity. Only companies with deep engineering resources, like SpaceX, could afford to redesign rockets from the ground up for reusability.

Is rocket reusability better for the environment?

Yes, but not in the way most people think. Reusable rockets don’t reduce emissions per launch - they still burn the same fuel. But because they replace dozens of expendable rockets, they reduce the total amount of materials mined, manufactured, and discarded. That cuts down on industrial waste, transportation emissions, and resource consumption over time.

What’s the biggest challenge to faster launch cycles?

The biggest challenge is inspection time. Even with automation, checking the heat shield, engine components, and avionics after each flight takes 20-30 days. NASA and SpaceX agree that thermal protection system inspection is the critical path. Until AI-driven predictive maintenance can reliably detect damage without physical disassembly, turnaround times won’t drop below a few days.

Can reusable rockets launch from anywhere?

Technically, yes - but practically, no. Reusable rockets need landing zones, refurbishment facilities, and regulatory approval. SpaceX uses Cape Canaveral, Vandenberg, and Kennedy Space Center because they have the infrastructure. Smaller launch sites can’t support the logistics of recovering and refurbishing boosters. That’s why most reusable launches still happen in a few key locations.

Will reusable rockets make space tourism affordable?

They’re already helping. Blue Origin and SpaceX have flown private astronauts using reusable vehicles. But true affordability - like $50,000 per seat - requires much higher flight rates and lower operational costs. Starship, with its goal of 100 launches per vehicle per year, could make that possible. Until then, space tourism remains a luxury for the wealthy.

11 Responses

So basically we’re turning space into the airline industry?? Wild. I never thought I’d see the day when rocket boosters get a maintenance schedule like my car. 80% cost drop?? That’s not innovation-that’s a goddamn revolution.

lol SpaceX be like 'hey we just made space cheap' while the rest of us still pay $20 for wifi. 🤡 also why is everyone acting like this is new? We had reusable shuttles in the 80s 😭

That heat shield inspection bottleneck is real. I’ve seen videos of the technicians with flashlights crawling over the tiles like archaeologists. It’s beautiful but so slow.

What’s fascinating is how this shifts the entire economic model. It’s not just about cost-it’s about predictability. When you can schedule a launch like a flight, you enable entire industries. Starlink, lunar logistics, even orbital factories become viable because the supply chain isn’t a lottery anymore. The real win isn’t the landing-it’s the cadence.

Wait… so you’re telling me the government didn’t know about this? That NASA spent billions on expendable rockets while SpaceX was secretly building a flying Tesla? 🤔 I’m not saying it’s a hoax-but why did the FAA still require 60-day gaps? And why are we still using the same launch pads from the 60s? Someone’s hiding something. This isn’t engineering-it’s a distraction. They’re using rockets to mask something bigger… maybe something in the upper atmosphere. You ever notice how no one talks about the contrails after launch? They don’t dissipate like normal jet trails. Something’s off.

But what about the environment?? They still burn rocket fuel!! So it's not green at all!! 😤

Interesting how the real bottleneck isn't tech-it's regulation. FAA's 30-60 day rule is like forcing a Formula 1 team to wait a month between pit stops. The tech is ready. The bureaucracy isn't. And honestly? That’s the most American thing here.

It’s wild how we treat space like a factory now. Back in the day, we called it exploration. Now it’s just logistics. I get the efficiency, but… does it still feel like wonder? Or just another supply chain?

They say it’s about cost, but let’s be real-this is about control. Who owns the launch pads? Who owns the data from Starlink? Who owns the orbital real estate? This isn’t progress-it’s colonization with a tech bro smile. And you think NASA’s just a partner? Nah. They’re the rent collector. Elon didn’t build a rocket-he built a monopoly with a rocket-shaped logo.

One must pause to reflect on the moral implications of commodifying the cosmos. To treat the heavens as a commercial corridor, to reduce the sublime to a cost-per-kilogram metric-it is not merely economic; it is metaphysical. Have we forgotten that space was once the domain of poets, not profit margins? The rhythm you speak of is not progress-it is the erosion of awe.

You wrote "PICA-X" with a hyphen, but the official name is "PICA-X"-no hyphen. Also, "turbopumps" is misspelled in one paragraph as "turbo pumps." And you said "1,000 launches by 2030"-but Morgan Stanley’s report says "up to 1,200." You should fact-check before posting.