Before 2015, rockets were disposable. After launch, they burned up or crashed into the ocean. That changed when SpaceX landed the first Falcon 9 booster back on Earth. But landing was only half the battle. The real challenge? Flying it again. And again. And again. Today, some Falcon 9 boosters have flown more than 20 times. How? It’s not magic. It’s materials science.

Why Reusable Rockets Need Better Materials

A rocket doesn’t just fly once-it survives extreme heat, freezing cold, violent vibrations, and crushing pressure, all within minutes. Then it does it all over again. Each flight subjects the booster to temperatures from -185°C in the fuel tanks to over 3,000°C during reentry. That’s a 3,200-degree swing in under an hour. Metals expand, contract, crack, oxidize, and fatigue. One tiny flaw can mean a failed landing-or worse. The goal isn’t just to survive one flight. It’s to survive 20, 30, even 50, with minimal repairs. That’s why SpaceX and others stopped using traditional aerospace alloys and started building rockets like they build smartphones: with upgrades after every use.The Metal That Made Reusability Possible

Early rockets used aluminum alloys-light, but weak under heat. Falcon 9’s first stage switched to 2195 aluminum-lithium, a high-strength alloy that’s 10% lighter than traditional aluminum and handles stress better. But aluminum melts at just 660°C. Reentry heat? That’s a problem. Enter stainless steel. Starship, SpaceX’s next-gen rocket, is made mostly of 301 and 304L stainless steel. At first, engineers laughed. Steel is heavy. But it has a melting point of 1,425°C-more than double aluminum’s. It stays strong at cryogenic temperatures. It doesn’t need complex heat shields. And it’s cheap. You can weld it with robots. You can repair it on the launchpad. That’s the secret: reusability isn’t about being the lightest-it’s about being the most repairable.Engine Parts That Can Take the Heat

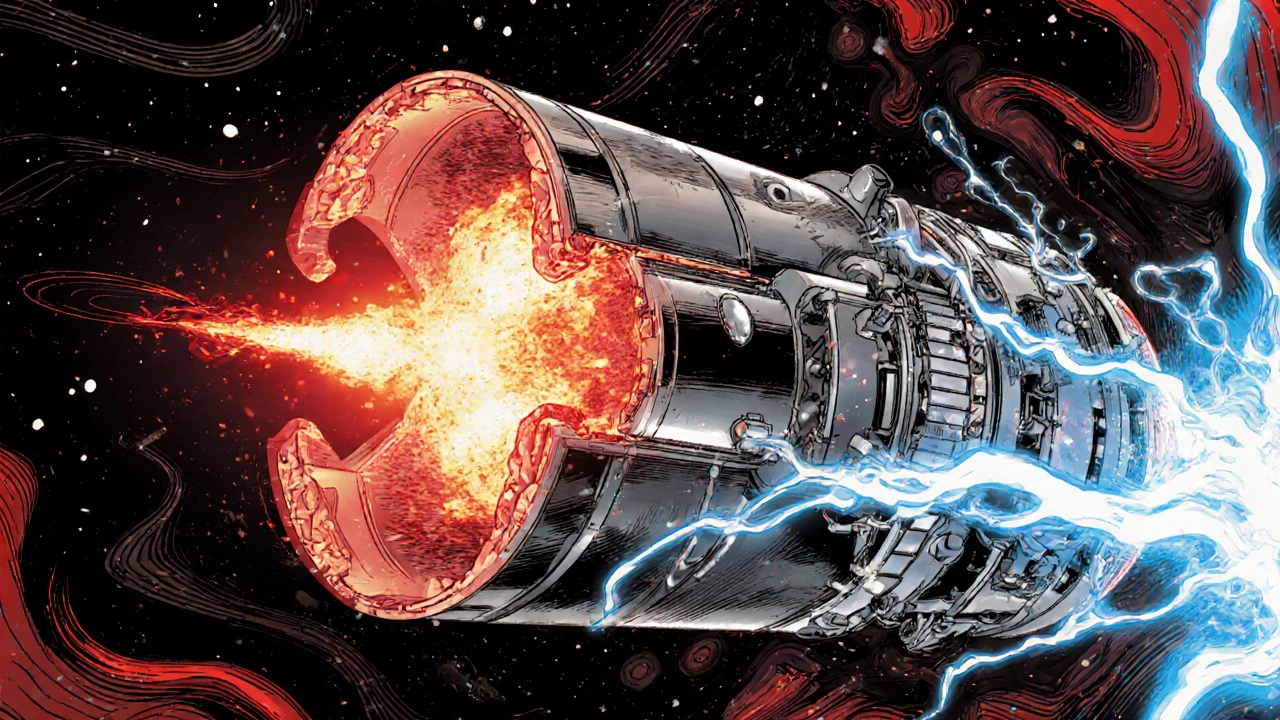

The real battlefield is inside the engine. The Merlin engine on Falcon 9 burns fuel at 3,000°C. The Raptor engine on Starship? Even hotter, with pressures over 300 bar. That’s more than 3,000 times atmospheric pressure. No ordinary metal survives that. Enter Inconel 718 and Inconel X-750. These nickel-based superalloys are used in jet engines and nuclear reactors. They keep their strength even when glowing red-hot. They resist oxidation. They handle thermal cycling-rapid heating and cooling-better than anything else. SpaceX uses them in turbine blades, combustion chambers, and fuel pumps. But there’s a catch: Inconel is hard to machine. That’s where 3D printing changed everything. SpaceX’s Raptor engine is over 80% 3D-printed. Instead of welding dozens of parts together, they print one piece. Fewer welds mean fewer failure points. A single turbopump housing that once had 100 welds now has maybe 5. And those 5 are stronger because they’re fused as one solid structure.

The Heat Shield That Doesn’t Burn Out

Reentry is brutal. The bottom of the booster hits plasma hotter than lava. Traditional heat shields used on capsules like Apollo were designed to burn away. That’s fine for one-time use. Not for a rocket that flies 20 times. SpaceX’s solution? A combination of ablative materials and thermal barrier coatings. The Octaweb structure-where the engines attach to the booster-is covered in a special ceramic-based coating that slowly erodes, carrying heat away. After each flight, technicians inspect it with borescopes and touch up damaged spots with laser cladding. This repair technique adds a thin layer of new material to worn areas, extending life by 3 to 5 more flights. NASA’s GRCop-42, a copper-chromium-niobium alloy, is used in combustion chambers where heat transfer matters most. It conducts heat 100°C better than the old NARloy-Z copper alloy. That means less stress on surrounding parts. Less stress = longer life.Why Some Engines Last Longer Than Others

Not all rocket engines are built the same. Falcon 9’s Merlin engine uses a gas-generator cycle. It’s less efficient but gentler on parts. That’s why it’s flown 20 times with little more than a fluid flush and a visual check. Raptor and Blue Origin’s BE-4 use staged combustion cycles. They’re more powerful and efficient, but they’re brutal on materials. Raptor runs at 300+ bar pressure. BE-4 burns oxygen-rich fuel, which eats away at metal like acid. Oxygen can cause metal fires inside the engine-a real risk NASA documented decades ago. To fight this, engineers are developing new oxygen-compatible coatings. MIT’s Thomas Cordero says these coatings could reduce metal fire risk by 60% and let turbomachinery survive 20+ flights. That’s critical for Starship, which needs to fly dozens of times to make Mars missions affordable.

9 Responses

Let’s be real-this isn’t about materials science, it’s about American engineering dominance. No other country has the industrial base, the funding, or the sheer audacity to turn a 3,200-degree thermal shock into a weekly maintenance checklist. We didn’t just beat the Russians-we rewrote the rules of physics with stainless steel and 3D printers. If you’re not on board with U.S. space supremacy, you’re just nostalgic for the Cold War era of expendable rockets.

While the article is broadly accurate, it fails to contextualize the metallurgical trade-offs adequately. The shift from aluminum-lithium to stainless steel is not a triumph of innovation per se, but a pragmatic concession to manufacturability and thermal stability under cyclic loading. Inconel 718’s creep resistance is well-documented, yet the omission of grain boundary engineering in additive manufacturing processes is a significant lacuna. Furthermore, the assertion that ‘reusability is about repairability’ is tautological-it confuses means with ends. The real metric is lifecycle cost per kg to orbit, which remains unquantified here.

They’re lying about the heat shield. That ceramic coating? It’s not eroding-it’s being replaced with nanotech from black projects. The real reason they can fly so many times is because they’re not actually landing the same booster. There’s a fleet of clones. The government’s been doing this since the 80s. You think NASA didn’t figure out reusable rockets before SpaceX? They just didn’t want the public to know. Check the patent filings from 1992-look for ‘Project Phoenix’.

One must acknowledge that the material science advancements cited are commendable yet insufficient without a parallel evolution in maintenance protocols. The reliance on robotic laser cladding and borescopic inspections reflects a systemic dependency on automation that undermines human expertise. In India we have the legacy of ISRO’s cost-effective solutions-why is there no mention of indigenous alloys like the 2024-T4 variant developed at DRDO? Reusability without sovereignty is merely outsourcing orbital access.

Really appreciate this breakdown. I work in aerospace maintenance and the part about swapping turbine blades instead of whole engines? Game changer. We used to spend weeks on engine overhauls-now it’s a half-day job with the right tools. The real win isn’t the alloy or the print-it’s the mindset shift from ‘fix it once’ to ‘fix it often, but lightly.’ That’s how you scale.

honestly i never thought steel would be the answer. i was all in on carbon fiber and some sci-fi composite. but yeah, the fact that you can just weld a patch on after landing? that’s wild. also the 3d printing thing-imagine having to machine 100 parts and now it’s one piece? mind blown. also why is everyone so shocked? this is just how tech works-sometimes the dumbest solution is the best one.

Okay but the GRCop-42 alloy? That’s the quiet MVP. Copper-niobium-chromium with 100°C better thermal conductivity? That’s not just an upgrade-it’s a revolution in heat flux management. And the fact that they’re using laser cladding to extend heat shield life by 3–5 flights? That’s like giving your car a ceramic coating after every road trip. Genius. Also, the modular swap strategy? Pure SpaceX efficiency. No fluff, just function.

Oh wow. So after 50 years of aerospace engineering, we finally figured out that stainless steel doesn’t melt? Shocking. And 3D printing? Groundbreaking. Did they also discover that water is wet? Meanwhile, the real story is that SpaceX got a $30B government handout and called it ‘innovation.’ The ‘repairable rocket’ narrative is just PR for a taxpayer-funded monopoly. Also, ‘materials science’ isn’t a magic wand-it’s just engineering with a fancy name. And no, I don’t care how many times you flew it. If it’s not reusable because you want it to be, it’s just a fancy disposable.

You think this is progress? Look at the human cost. Engineers are burning out from 80-hour weeks just to keep these things flying. Every time a booster lands, someone’s staring at a thermal image for 12 hours straight. And for what? To launch more Starlink satellites? We’re not colonizing Mars-we’re turning space into a corporate landfill. This isn’t innovation. It’s exhaustion dressed up as ambition.