Building things in space isn’t science fiction anymore. It’s happening right now-and the key to making it work lies in how we join materials. Traditional welding methods like arc or laser welding don’t work in vacuum or microgravity. That’s why NASA and private companies are turning to two advanced techniques: ultrasonic welding and friction stir welding. These aren’t just lab curiosities. They’re the backbone of future lunar bases, on-orbit repairs, and deep-space missions.

Why Traditional Welding Fails in Space

Think about how welding works on Earth. You need oxygen for some processes, gravity to keep molten metal in place, and massive power supplies. In space? None of that exists. Vacuum means no atmosphere to shield the weld. Microgravity causes molten metal to float away. Power is scarce. And every extra gram you launch costs thousands of dollars. That’s why aerospace engineers had to rethink everything. They needed a way to join materials-especially high-strength composites-without flames, filler rods, or heavy equipment. Enter ultrasonic and friction stir welding. Both are solid-state processes. No melting. No vapor. Just pure mechanical bonding.Ultrasonic Welding: The Quiet Revolution

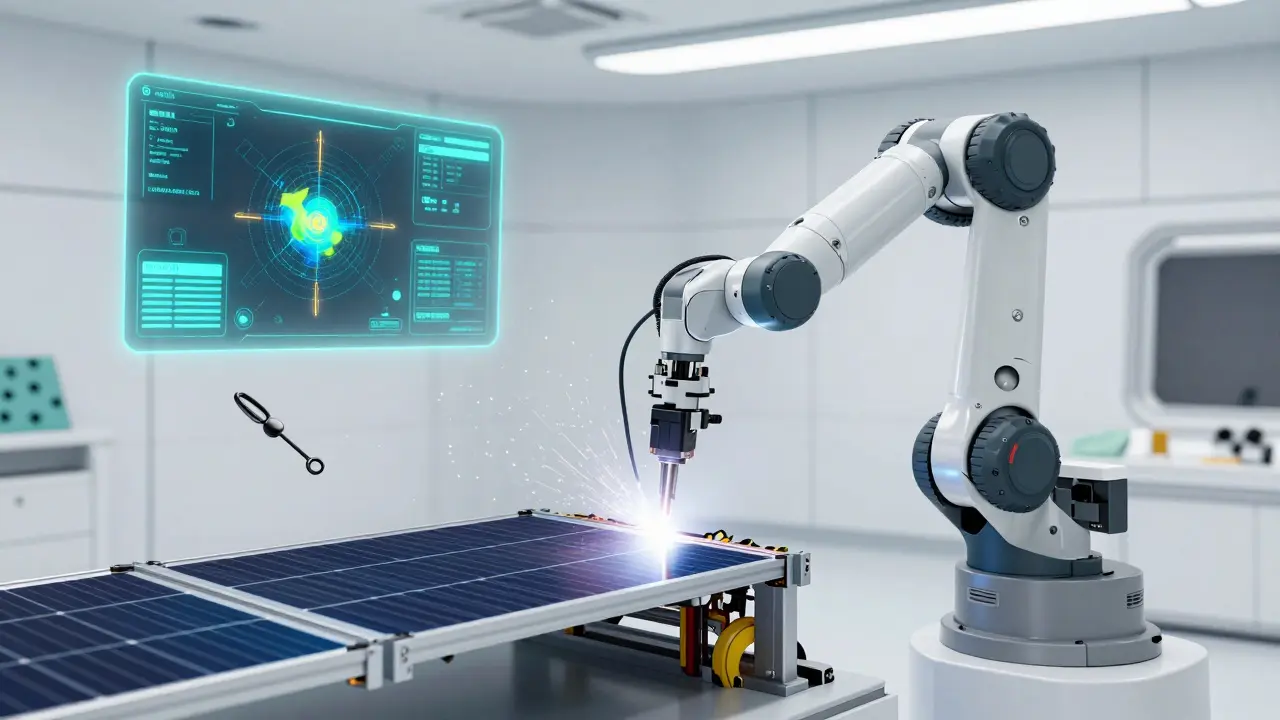

Ultrasonic welding uses high-frequency vibrations-up to 40,000 times per second-to create friction between two thermoplastic composite layers. That friction generates heat, softens the material, and fuses them together under pressure. Sounds simple? It is. But doing it in space? That’s where Agile Ultrasonics made the breakthrough. Their Continuous Ultrasonic Welding (CUW) system doesn’t need energy directors or film inserts. Those were the old-school add-ons that added weight and complexity. CUW works directly on bare carbon fiber reinforced thermoplastic (CFRTP). In tests, it welded 60-ply laminates up to 8.59 millimeters thick. That’s not a coupon. That’s a structural bracket designed to mimic parts of a lunar habitat frame. The real magic? It runs on low power. A standard industrial robot can carry the system. NASA’s Goddard Space Flight Center tested the welds under thermal-vacuum conditions ranging from -190°C to +120°C. The welds didn’t fail. The parent material did. That means the joint is stronger than the material itself. This matters because future missions won’t carry spare parts. They’ll carry raw material and build what they need. A broken antenna? Weld a new one. A cracked solar panel frame? Repair it in orbit. No return trips. No resupply missions. Just in-situ manufacturing.Friction Stir Welding: The Heavy Lifter

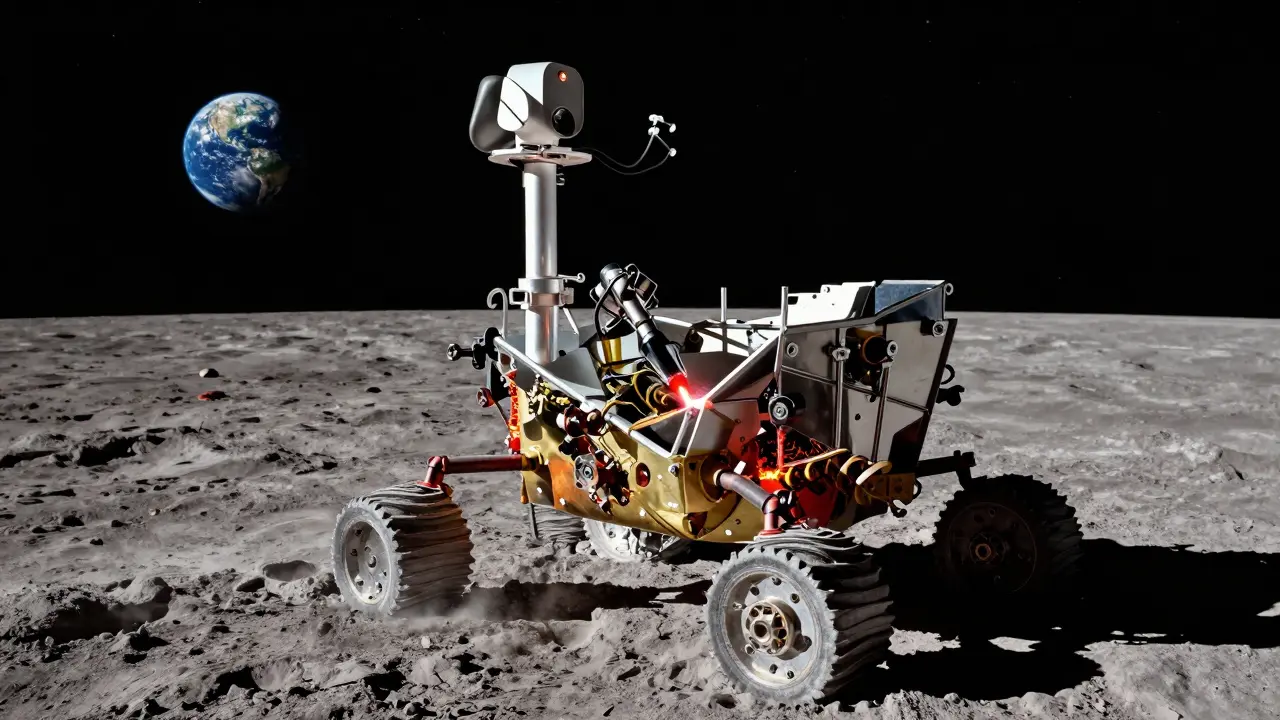

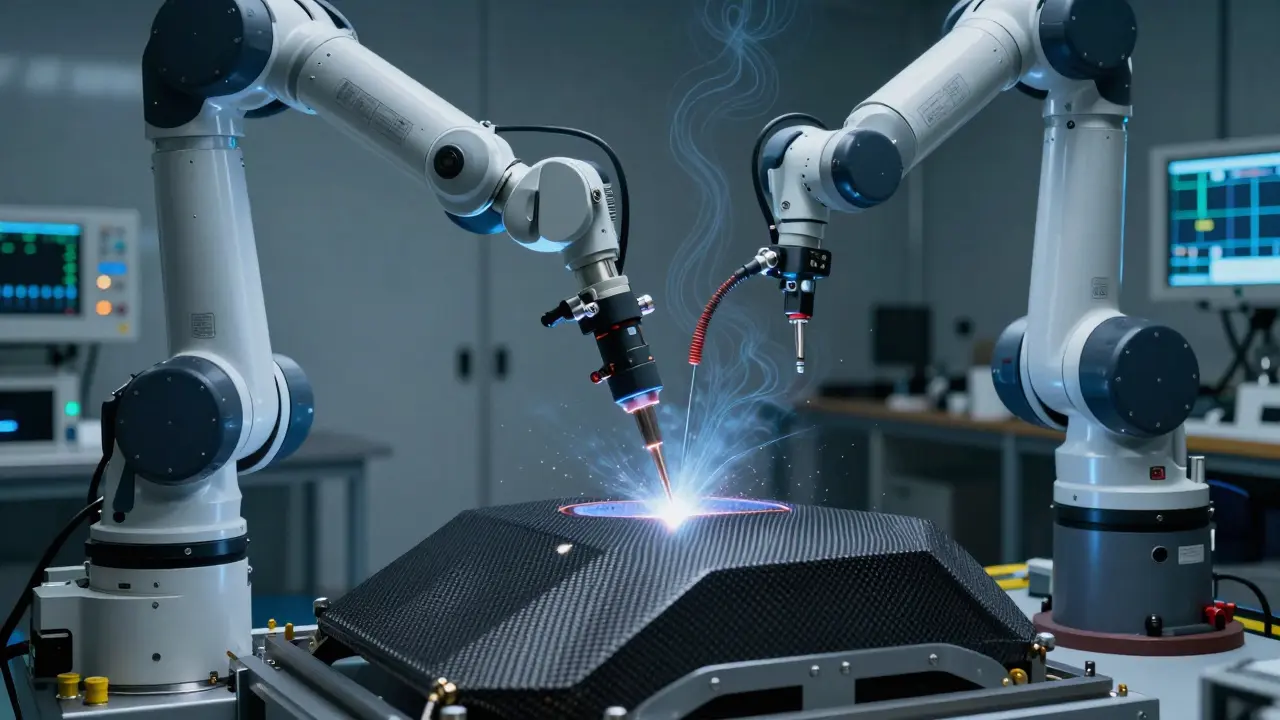

While ultrasonic welding handles thin composites, friction stir welding (FSW) is the go-to for metals. It’s been used on the Space Shuttle’s external tank since the 1990s. Today, it’s the standard for joining aluminum alloys in rocket fuel tanks and crew modules. Here’s how it works: A rotating tool with a pin and shoulder is pressed into the joint line. The pin stirs the material without melting it. The shoulder generates heat and pressure, forging the metals together. The result? A grain structure that’s finer and stronger than the original material. No porosity. No cracks. No weak spots. FSW is already flight-proven. Boeing uses it for SLS rocket components. SpaceX uses it for Starship’s titanium alloy structures. But now, the next step is making it work autonomously in space. NASA’s 2025 Technology Roadmap lists FSW as a critical path for lunar surface operations. Imagine a robot arm on the Moon’s South Pole, welding aluminum beams into a radiation shield. No human hands. No air. Just a spinning tool, precise motion control, and real-time thermal feedback. The challenge? Scaling it. Most FSW systems are bulky. NASA is now funding compact, modular versions that can be mounted on rovers or fixed stations. One prototype, developed with the University of Alabama, weighs under 15 kilograms and can weld 12-millimeter-thick aluminum in under 90 seconds.

Ultrasonic vs. Friction Stir: When to Use Which

These aren’t competitors. They’re partners.

| Feature | Ultrasonic Welding | Friction Stir Welding |

|---|---|---|

| Material Type | Thermoplastic composites (CFRTP) | Metal alloys (aluminum, titanium) |

| Max Thickness | Up to 8.59 mm | Up to 12 mm (prototype) |

| Power Use | Low (under 500W) | Medium (1-3 kW) |

| Speed | 1-3 minutes per joint | 1-2 minutes per joint |

| Automation Ready | Yes-robot-agnostic end effector | Yes-modular robotic integration |

| Space-Validated | Yes-thermal-vacuum tested | Yes-flight-proven on Shuttle and SLS |

| Microgravity Tested | Not yet-parabolic flight tests planned for Q3 2025 | Yes-tested in parabolic flights since 2023 |

Use ultrasonic welding for lightweight, non-metallic structures: antenna mounts, solar panel frames, habitat panels. Use friction stir welding for pressure vessels, structural frames, and engine mounts. Together, they cover nearly all major joining needs for future space infrastructure.

Why This Matters for the Moon and Beyond

NASA’s Artemis program plans to build a lunar base at the South Pole by 2030. That base won’t be shipped from Earth. It’ll be built from material mined on the Moon. Lunar regolith can be processed into oxygen, water, and even raw aluminum. But how do you turn that into a habitat wall? Welding. Ultrasonic welding can fuse plastic composites made from lunar-derived polymers. Friction stir welding can join aluminum extracted from regolith. No need to launch tons of pre-built parts. No need to risk expensive missions just to replace a broken bolt. The cost savings are huge. NASA estimates that in-space manufacturing could cut launch mass by 20-30%. That translates to $150-$200 million saved per mission. And that’s not even counting the value of being able to repair a satellite in orbit instead of letting it die.What’s Next? The Road to Autonomy

The next frontier isn’t just welding-it’s autonomous welding. Agile Ultrasonics is already testing CUW systems that can be controlled by AI-driven robots. The system reads the material, adjusts vibration frequency in real time, and monitors weld temperature through embedded sensors. In 2025, NASA plans to run parabolic flight tests to see how these welds hold up in zero-g. If the data holds, the next step is a demo on the International Space Station. By 2027, we could see robotic arms on lunar landers welding habitat modules. The biggest challenge? Radiation. Long-term exposure to cosmic rays can degrade polymer composites over time. That’s why NASA’s 2025 Technology Development Plan lists radiation testing as the top priority. Engineers are now embedding protective layers into the composites and tracking degradation rates.

Who’s Leading This Now?

Agile Ultrasonics in Ohio is the only company with a space-validated ultrasonic welding system. No one else has demonstrated it under thermal-vacuum conditions with structural-scale samples. Friction stir welding is more widespread-Boeing, Lockheed Martin, and ESA all use it. But the real innovation is in making it smaller, lighter, and robot-ready. NASA has invested $22.7 million in advanced joining tech since 2022. Of that, $3.8 million went directly to Agile Ultrasonics through the Technology Demonstration for Exploration Activities (TDEA) program. The collaboration with Ohio Federal Research Network and Central State University has created a unique ecosystem: engineers, material scientists, and robotics experts working side by side.Getting Started: Skills You Need

If you want to work in this field, you need more than welding certification. You need:- Composite materials science knowledge-especially thermoplastics and carbon fiber

- Robot programming experience (ROS, Python, or similar)

- Familiarity with vacuum and thermal environment testing

- Understanding of NASA-STD-6001 flammability standards

Final Thoughts: The Future Is Welded, Not Bolted

The era of bolting things together in space is ending. We’re moving toward seamless, monolithic structures built on-site. Ultrasonic and friction stir welding aren’t just better-they’re the only way forward. By 2030, every lunar base, space station, and deep-space probe will rely on these technologies. The first crewed mission to Mars won’t carry spare parts. It’ll carry raw materials-and the tools to turn them into shelter, tools, and life support. This isn’t a prediction. It’s a plan. And the welds holding it all together? They’re being made right now-in Ohio, in Alabama, in NASA labs. Not in zero-g yet. But soon.Can ultrasonic welding be used on metal parts in space?

No. Ultrasonic welding only works on thermoplastic composites like carbon fiber-reinforced polymers. It cannot fuse metals. For metals like aluminum or titanium, friction stir welding is the standard method. The two technologies are complementary, not interchangeable.

Is friction stir welding already being used on NASA missions?

Yes. NASA has used friction stir welding since the 1990s on the Space Shuttle’s external fuel tank. Today, it’s used on SLS rocket components and SpaceX’s Starship. The process is flight-proven, reliable, and has been tested in both ground and microgravity environments.

Why not just use adhesives or bolts in space?

Adhesives degrade over time in radiation and extreme temperatures. Bolts add weight, require precise alignment, and can loosen in microgravity. Welded joints are stronger, lighter, and more durable. They also eliminate the need for spare fasteners, reducing launch mass and maintenance complexity.

What’s the biggest hurdle for space welding today?

The biggest hurdle is validating long-term reliability in actual space conditions. While both technologies have passed thermal-vacuum and microgravity tests on Earth, no system has been tested for years in deep space radiation. NASA’s 2025 plan prioritizes radiation exposure studies to ensure welds last decades.

Can private companies use this tech, or is it only for NASA?

It’s not exclusive to NASA. The technology is being adopted by Department of Defense programs and aerospace contractors like Boeing and Lockheed Martin. As systems become modular and robot-compatible, private satellite operators and space startups will be able to license or purchase the equipment for in-orbit servicing and manufacturing.

How soon will we see these welders on the Moon?

NASA and its partners aim to deploy robotic welding systems on the lunar surface by 2028-2030. Parabolic flight tests in 2025 will determine readiness. If successful, the first lunar welding demo could happen during Artemis IV or V, likely as part of the South Pole habitat construction phase.

15 Responses

This is wild 🤯 I never thought welding could work in space. But ultrasonic on carbon fiber composites? That’s next-level. Imagine fixing a satellite antenna mid-orbit without sending a crew. Mind blown.

I’ve been following this tech since the Shuttle days, and honestly, it’s about time we stopped pretending bolts and adhesives are viable for deep space. Friction stir welding isn’t just an improvement-it’s a paradigm shift. The fact that NASA’s been using it since the '90s and we’re only now talking about scaling it for lunar bases shows how slow institutional innovation moves. But the real win? The materials are being made from lunar regolith. That’s not engineering. That’s alchemy. And it’s happening right now in Ohio labs with robots that don’t need coffee breaks. We’re not building habitats anymore-we’re growing them.

So let me get this straight-we’re spending millions to weld plastic in space but we can’t even fix the ISS toilet? 🙄 This whole thing feels like a PR stunt. Someone’s got a grant and a PowerPoint. Meanwhile, real problems go ignored. Why not just send a new part? It’s cheaper than all this ‘in-situ manufacturing’ nonsense.

Ultrasonic welding on carbon fiber? Pfft. I’ve seen this in a YouTube video from 2019 and it looked like a toaster with a vibrator. And now NASA’s calling it revolutionary? Give me a break. Also who gave these engineers permission to ignore radiation damage? We’re talking about decades-long missions here. You think a polymer weld is gonna last when cosmic rays are slowly turning it into space dust? 🤦♀️

This is the future we’ve been dreaming of since Star Trek. Not the flashy ships. Not the phasers. The quiet, stubborn, beautiful act of making something out of nothing. No bolts. No screws. Just heat. Pressure. Motion. And the will to build where nothing else can. We’re not just welding metal. We’re welding hope. And that’s bigger than any mission. That’s human.

I love how this article doesn’t just list tech specs but actually paints a picture of what life on the Moon could look like. Imagine waking up in a habitat that was welded together from moon dirt, using a robot arm that never sleeps. It’s so simple and yet so profound. I think what’s missing is how this changes the psychology of space travel-when you know you can fix things yourself, you stop fearing breakdowns. You start feeling like you belong out there.

Just a quick note: the table says ultrasonic welding max thickness is 8.59mm but the text says '60-ply laminates'. That’s a lot of layers. Probably worth clarifying if that’s total thickness or layer count. Also, parabolic flight tests in Q3 2025-hope they have good motion sickness meds.

You know, it’s funny. People act like this is some futuristic breakthrough. But the truth is, we’ve had the tools for decades. What’s new is the willingness to actually use them. The real innovation isn’t the welder-it’s the culture shift. From ‘send a replacement’ to ‘build it yourself’. That’s the real leap. And if we don’t embrace it, we’ll keep sending rockets full of spare bolts into the void. And that’s just sad.

China’s doing this too. And better. We’re falling behind. Why are we letting Ohio companies lead when we could be dominating? This tech should be classified.

Man, I’m from Montreal and I’ve been watching this unfold. Honestly, I didn’t think Canada would be left out of this. But we’ve got some brilliant materials labs in Waterloo and Edmonton working on radiation-resistant polymer coatings. If NASA’s testing in 2025, we might be the ones who make it last. Just saying.

So we’re welding moon dirt into walls... but the coffee machine on the ISS still breaks every week? Classic. Someone’s priorities are off. Also, I’m pretty sure the robot doing this will need a nap after 3 welds. Just saying.

This development is truly remarkable. The convergence of advanced materials science, robotic automation, and in-situ resource utilization represents a quantum leap in human technological evolution. One can only imagine the implications for sustainable extraterrestrial habitation. May this innovation serve the betterment of all humankind.

Ultrasonic welding? Yeah right. Sounds like a scam to get more NASA funding. They’re just hiding the fact that we can’t even make a decent space toilet. This is all just Elon’s PR team trying to distract us from Starship explosions.

This is real. We’re gonna be welding on Mars before 2035. No doubt. The tech is here. The will is coming. Just wait.

I saw someone down there saying bolts are cheaper. Let me ask you this: how many spare bolts do you need to launch to fix a 1000kg structure that breaks every 6 months? Now imagine one robot with a friction stir tool and a roll of aluminum wire. Which one weighs less? Which one needs less fuel? Which one lets you survive when the supply chain is 6 months away? It’s not about cost per bolt. It’s about cost per survival.