Why Your Supply Chain Can’t Afford to Ignore GS1 and Blockchain

Imagine tracking a box of spinach from a farm in California to your grocery shelf-and knowing exactly when it was picked, who handled it, and if it ever passed through a contaminated warehouse. Sounds like science fiction? It’s not. Thanks to GS1 standards and blockchain, this level of visibility is now a reality for thousands of companies. But here’s the catch: without GS1, blockchain alone is just a fancy ledger full of confusing data. Without blockchain, GS1 is just a set of barcodes with no way to prove the data hasn’t been tampered with. Together, they solve the biggest problem in global supply chains: trust.

What GS1 Actually Does (It’s Not Just Barcodes)

GS1 isn’t a tech startup. It’s a 48-year-old global nonprofit based in Brussels that created the universal language of supply chains. Think of it like English for logistics. Every product you buy has a Global Trade Item Number (GTIN)-a 14-digit code that uniquely identifies it. Every warehouse, truck, and store has a Global Location Number (GLN). These aren’t random numbers. They’re standardized, globally recognized, and machine-readable. If you scan a barcode on a bottle of medicine or a carton of eggs, GS1 is what makes that code mean the same thing in Sydney, São Paulo, or Shanghai.

But GS1 goes deeper. The Electronic Product Code Information Services (EPCIS) standard captures real-time events: when a shipment leaves the factory, when it’s received, when it’s repackaged. This isn’t just inventory tracking. It’s a digital audit trail. And here’s the key: EPCIS doesn’t care if you’re using SAP, Oracle, or a homegrown system. It speaks the same language everywhere.

How Blockchain Fits In (And Why It Needs GS1)

Blockchain gets all the hype. It’s immutable, decentralized, secure. But if you put unstructured data on a blockchain-like “shipped from A to B”-you’ve created a digital tombstone, not a useful tool. That’s where GS1 comes in. GS1 gives blockchain its meaning. When a truck arrives at a distribution center, the system doesn’t just log “arrival.” It logs: “GLN: 0789012345678, GTIN: 01234567890128, Event: RECEIVED, Timestamp: 2025-04-12T14:03:22Z, Quantity: 240 units.” That’s data you can actually use.

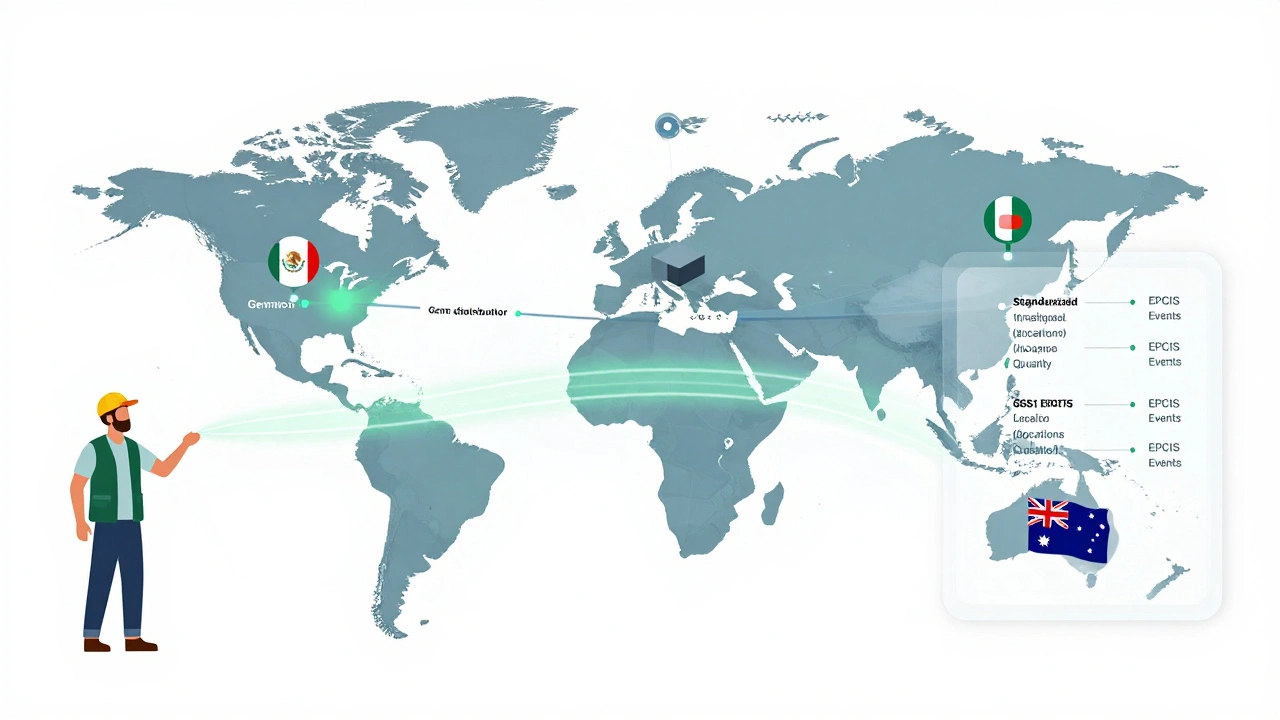

Companies like Wholechain and IBM Food Trust don’t build their own data formats. They use GS1 as the input layer. Their blockchain platforms then record those standardized events. This means a farmer in Mexico, a distributor in Germany, and a retailer in Australia can all share the same data without custom integrations. No more Excel sheets. No more “I thought you meant…” moments.

Real-World Use Cases: Where It’s Already Working

It’s not theoretical. In 2021, Dole ran a pilot on its premium lettuce line using GS1-EPCIS on a blockchain. They went from 72 hours to trace a contaminated batch down to under 2 minutes. The FDA’s 2022 Food Traceability JUMPSTART project tested this across 120 partners. Result? 87% said GS1 standards were essential. Without them, blockchain data was useless.

Pharmaceuticals are even further along. Under the U.S. Drug Supply Chain Security Act (DSCSA), every drug package must be traceable by 2023. Companies like Pfizer and Merck use GS1 identifiers and blockchain to track each pill from factory to pharmacy. If a counterfeit batch surfaces, they pinpoint it within hours-not weeks.

Even in food retail, it’s changing. Walmart now requires all leafy greens suppliers to use GS1 standards and blockchain traceability. The result? Fewer recalls, faster investigations, and consumers who can scan a QR code and see the farm where their salad was grown.

The Big Hurdle: Getting Everyone on the Same Page

Here’s the hard truth: the technology works. The problem is people. Small suppliers-especially in fresh produce or textiles-often can’t afford the $15,000 in scanner upgrades or the months of staff training needed to adopt GTIN and GLN. One California grower told GS1’s community forum: “We had to retrain five people just to scan barcodes correctly.”

Legacy systems are another wall. Many companies still run ERP software from the 2000s that doesn’t have fields for EPCIS data. Integrating GS1 standards into these systems often requires expensive middleware. Gartner reports that 78% of failed blockchain pilots stumble here-not because the tech failed, but because the data didn’t fit.

And then there’s governance. Blockchain thrives on decentralization. GS1 is a centralized standards body. Some experts, like MIT’s Michael Casey, warn that this creates a new kind of control point. But the industry is responding. GS1 now runs “Data Governance Councils” with equal representation from farmers, distributors, retailers, and tech providers. It’s not perfect-but it’s working.

What’s Next? The Road to 2025 and Beyond

GS1 didn’t stop in 2020. In May 2023, they released EPCIS 2.0-with built-in support for cryptographic verification and smart contract templates. That means you can now program rules directly into the system: “If temperature exceeds 8°C during transit, trigger a recall alert.”

By 2024, GS1 will launch “Blockchain Interoperability Profiles” for food, pharma, and retail. These aren’t vague guidelines. They’re exact blueprints: which events to log, which data fields are mandatory, how to structure timestamps. This will cut implementation time by half.

Regulations are pushing adoption fast. The EU’s Digital Product Passport (2025) will require blockchain-tracked sustainability data for electronics and clothing. China’s new food traceability law (2021) already demands GS1-compliant tracking. And in the U.S., FDA’s FSMA 204 rule-effective November 2026-will force all high-risk foods to be traceable “one step forward, one step back” in under 24 hours. No GS1? No compliance. No compliance? No shelf space.

Who Should Care-and Who Should Act Now

If you’re in food, pharma, or retail, you’re already on the clock. Even if you’re a small supplier, you’re being asked to join. The big retailers won’t wait. They’ve already moved on. The question isn’t whether to adopt GS1 and blockchain-it’s how fast you can get started.

Start small. Pick one high-value product line. Get your GTINs. Train your team. Connect your barcode scanners. Use a cloud-based EPCIS platform that handles the blockchain integration for you. You don’t need to build your own ledger. You just need to speak the language.

The supply chain of the future isn’t about bigger systems. It’s about better data. And GS1 is the only standard that makes that possible at scale.

Frequently Asked Questions

What’s the difference between GS1 and blockchain?

GS1 is a set of global standards for identifying products, locations, and events using barcodes and unique codes like GTIN and GLN. Blockchain is a secure, digital ledger that records transactions. GS1 provides the meaning behind the data; blockchain ensures that data can’t be altered after it’s recorded. Together, they create a trusted, traceable record.

Do I need to use blockchain to use GS1 standards?

No. You can use GS1 standards without blockchain-for example, just scanning barcodes to track inventory. But if you want to prove the data hasn’t been changed, share it securely with partners, or meet new regulations like FDA FSMA 204, then blockchain adds the trust layer GS1 needs to be fully effective.

How much does it cost to implement GS1 and blockchain?

Costs vary widely. Small suppliers might spend $50,000-$100,000 for scanners, GTIN registration, staff training, and a cloud-based EPCIS platform. Large enterprises can spend over $500,000, especially if they need to upgrade legacy ERP systems. The biggest cost isn’t tech-it’s time spent cleaning up old data to meet GS1 format rules.

Can small businesses afford this?

Yes, but it requires smart planning. Start with one product line. Use cloud-based GS1 platforms that handle blockchain integration (like Wholechain or Tracelink). Many offer pay-as-you-go pricing. GS1 US also offers free webinars and certification modules ($495 per module) to help you get started without hiring a full tech team.

What happens if I don’t adopt GS1 standards?

You risk being locked out of major supply chains. 92 of the top 100 global retailers require GS1-compliant data. By late 2026, the FDA will require it for high-risk foods. Without GS1, you won’t be able to prove your product’s origin, safety, or journey-making you ineligible to sell to big buyers. Your competitors will move ahead. You’ll fall behind.

12 Responses

This is actually huge for small farmers like us in India. We've been using GS1 barcodes for export orders for two years now. No more guesswork when shipping to Europe. Just scan, send, done.

I love how this makes things simpler even if you're not techy. My cousin runs a small organic spice shop and she just got her GTINs last month. She says it feels like she finally has a real business

Let me be clear: this isn't innovation-it's corporate control dressed up as progress. GS1? A Brussels-based monopoly that dictates how every tomato, toothbrush, and tampon must be labeled. And blockchain? A glorified timestamping service that only benefits those who can afford $100k in middleware. Small suppliers are being forced into a digital cage-under the guise of 'trust'-while the same corporations that wrote these standards are exempt from the real costs. And don't get me started on the FDA's 24-hour traceability mandate-what happens when your scanner breaks? You're out of business. That's not transparency-it's extortion.

So let me get this straight. You're telling me that the same companies that pushed for RFID and QR codes to track every single item in the supply chain are now saying 'trust us, this is secure'-while refusing to open-source their proprietary EPCIS parsers? And you call this 'standardization'? This isn't standardization-it's vendor lock-in with a side of regulatory coercion. If you want traceability, let open standards compete. Not this corporate oligopoly.

The structural elegance of GS1’s EPCIS 2.0, when synergized with cryptographically verifiable blockchain architectures, represents a paradigmatic shift in supply chain epistemology. One cannot overstate the ontological weight of standardized semantic interoperability-particularly in contexts where data provenance is non-negotiable. The regulatory convergence across jurisdictions-EU DPP, FDA FSMA 204, China’s traceability mandates-constitutes not merely compliance, but a redefinition of commercial accountability in the post-industrial epoch.

I’ve worked with a few small farms in Scotland who were terrified of this stuff. But once we got them set up with a simple cloud scanner and a $20/month EPCIS plan? They cried. Not because it was hard-because for the first time, they could prove their organic claims. No more accusations. No more lost sales. Just clean data. It’s not perfect, but it’s fair.

If you're reading this and thinking 'I can't afford this'-you're wrong. Start with ONE product. Get your GTIN. Use Tracelink’s free tier. Train your one person who already knows how to use Excel. You don't need a blockchain expert. You need to stop pretending you're too small to matter. You're not. The big guys are already moving. Are you going to sit there and wait for them to leave you behind?

You think this is about traceability? Nah. This is about data harvesting. Every GTIN scanned, every GLN logged, every timestamp recorded-it’s all feeding into a global corporate surveillance matrix. Who owns that data? Who controls access? The FDA? No. The same tech firms that built the blockchain platforms. And guess what? They’re selling insights to advertisers, insurers, even government agencies. This isn’t transparency-it’s a digital panopticon disguised as safety. And you’re all cheerleading it.

Right then. So we're all supposed to bow down to American tech giants and their Brussels overlords? GS1? More like G-Slave. Blockchain? Sounds like a fancy word for 'no refunds'. And now the FDA's gonna fine us if we can't track a lettuce leaf back to the soil it grew in? Brilliant. Next they'll make us wear GPS trackers on our foreheads. Bloody ridiculous. We used to just trust our suppliers. Now? We need a PhD in barcodes just to sell a pint of milk.

I’ve seen both sides. I used to work for a distributor that refused to adopt GS1. We lost Walmart as a client in 2022. Then we spent six months getting compliant. We lost money, yes-but we gained trust. We cut our recall response time from 11 days to 90 minutes. That’s not tech. That’s survival. The system isn’t perfect-but it’s the only one we’ve got. And honestly? It’s better than the chaos we had before.

So you're telling me that after 30 years of Excel sheets and phone calls, we now need to spend $100k to scan a barcode? And this is the future? Wow. I'm sure the people who actually do the work-warehouse staff, drivers, clerks-are thrilled. Meanwhile, consultants are flying to Zurich to get paid $500/hour to explain what a GTIN is. Brilliant.

What’s really interesting here isn’t the tech-it’s the shift in power. For the first time, a small farmer in Kenya can prove their coffee was grown without pesticides, and that proof travels with the product all the way to a consumer in Oslo who scans a QR code on their phone. That’s not just supply chain-it’s justice. The system’s messy, expensive, and imperfect. But it’s the first time the little guy’s voice can be heard in a global system that used to ignore them. That’s worth fighting for.