When you step inside a space habitat, the air you breathe isn’t just a mix of oxygen and nitrogen - it’s the result of meticulous material choices and strict contamination control. One tiny mistake in material selection can turn a life‑support system into a source of invisible pollutants that jeopardize crew health and mission success. This guide walks you through why offgassing matters, how NASA’s standards keep the air clean, and what practical steps engineers take to pick the right materials for the next generation of orbital homes.

What is offgassing and why it matters in a closed‑loop environment

Offgassing is the release of volatile organic compounds (VOCs) from solid materials when they are exposed to vacuum, temperature extremes, or radiation. In a spacecraft, those VOCs don’t disperse into the atmosphere; they linger, condense on optics, clog filters, and can react with other life‑support chemicals. Even parts‑per‑billion concentrations of formaldehyde or aromatic hydrocarbons have been shown to degrade optical coatings and irritate crew members, turning a tiny stream of molecules into a mission‑critical problem.

NASA’s hard‑line outgassing benchmark - ASTM E595‑21

The baseline for any material bound for a crewed habitat is the ASTM E595‑21 spec. It demands two key metrics after a 24‑hour vacuum bake at 125 °C:

- Total Mass Loss (TML) < 1.0 % - the overall weight lost from the sample.

- Collected Volatile Condensable Materials (CVCM) < 0.10 % - the amount that actually condenses on a cold surface.

Materials that miss either limit risk contaminating thermal radiators, scientific instruments, or the cabin’s air‑revitalization loop. NASA estimates that adhering to these limits can shave up to 30 % off the total anomalies linked to environmental contamination.

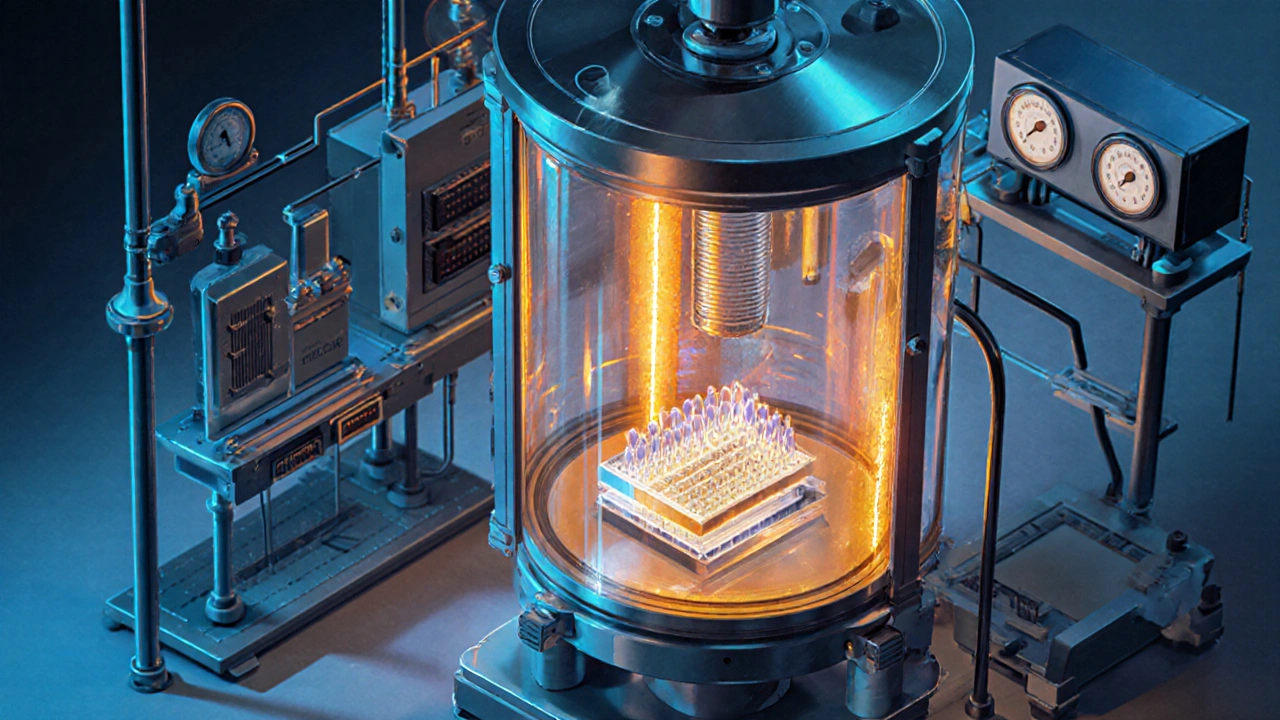

How engineers measure TML and CVCM

The test process is straightforward but precise. A sample is placed in a vacuum chamber, heated to the required temperature, and weighed before and after the bake. The volatile condensate is collected on a chilled quartz crystal, then weighed separately. The resulting percentages become the material’s compliance score in NASA’s public outgassing database, which now holds more than 5,000 entries.

Material families side‑by‑side

| Material type | Typical TML % | Typical CVCM % | Key pros | Key cons |

|---|---|---|---|---|

| Aluminium alloy (e.g., 6061‑T6) | 0.2‑0.5 | 0.02‑0.04 | High strength‑to‑weight, excellent thermal conductivity | Requires precision machining, higher cost than steel |

| Ceramic‑encapsulated electronics | 0.1‑0.3 | 0.01‑0.03 | Very low outgassing, radiation tolerant | Expensive, brittle handling |

| Polyimide‑based PCB (space‑grade) | 0.3‑0.5 | 0.02‑0.05 | Flexible, good dielectric, passes ASTM E595 | Long lead times, higher material cost |

| Standard FR‑4 PCB | 1.5‑2.5 | 0.2‑0.5 | Low cost, widely available | Fails NASA limits, requires bake‑out or replacement |

| Epoxy adhesives (space‑qualified) | 0.4‑0.8 | 0.05‑0.09 | Strong bonding, stable under thermal cycling | Limited suppliers, long qualification cycles |

Notice how metals and ceramics comfortably sit under both limits, while polymer‑based solutions need special formulations or additional bake‑out steps to stay compliant.

Beyond the numbers - the Z‑transformation method for smarter selection

Traditional selection often focused only on TML and CVCM. The 2010 Z‑transformation approach adds mechanical strength, thermal expansion, and radiation resistance into a single ranking score. Studies showed a 22 % boost in reliability when the method was applied to a set of 1,700 candidate components. In practice, engineers feed each material’s properties into a spreadsheet, apply the Z‑score, and compare the resulting index against mission‑specific thresholds. The result is a balanced shortlist that respects both contamination limits and structural performance.

Practical steps to keep the cabin air clean

- Early material heritage review - Start the design phase by pulling data from NASA’s outgassing database. Flag any high‑TML, high‑CVCM items before detailed CAD work begins.

- Specify space‑grade alternatives - Replace standard FR‑4 with polyimide or ceramic‑packaged boards wherever possible.

- In‑process bake‑out - Perform a 24‑48 hour vacuum bake at 100‑120 °C for all assembled sub‑systems. This alone can cut VOC release by up to 50 %.

- Ventilation design - Incorporate vent holes every 5‑10 cm on payload enclosures to promote gas diffusion during bake‑out and in‑orbit venting.

- Cleanroom assembly - Build components in ISO Class 5 (or better) environments. Even a single speck of dust can become a source of outgassed organics later.

- Real‑time monitoring - Equip the habitat with VOC sensors capable of detecting 10 ppb. The Orion program’s recent sensors provide early warning before concentrations build up.

Following these steps not only keeps the crew healthy but also protects sensitive optics, thermal radiators, and the water‑reclamation loop from fouling.

Supply‑chain realities you can’t ignore

Low‑outgassing adhesives, specialized coatings, and space‑grade PCBs often have lead times of six to twelve months. Plan material procurement right at the concept‑review stage; otherwise you risk redesigns that cascade into schedule overruns and budget spikes.

Future trends - in‑situ monitoring and water sorption

NASA’s next‑generation outgassing database will include water‑sorption metrics, acknowledging that absorbed moisture can desorb later and create condensation problems inside cryogenic modules. ESA’s new screening protocol now tests materials at multiple temperatures to mimic the thermal cycling that ranges from -150 °C to +120 °C in low‑Earth orbit. The vision for 2030‑plus habitats includes embedded sensors that continuously log VOC levels, feeding the life‑support software to adjust filtration and activate supplemental bake‑out cycles if thresholds are crossed.

Quick reference checklist for designers

- Validate every material against ASTM E595‑21 (TML < 1 %, CVCM < 0.1 %).

- Prefer metals, ceramics, and polyimide‑based polymers over standard plastics.

- Run a Z‑transformation ranking to balance mechanical and environmental factors.

- Schedule a 24‑48 h vacuum bake for all assemblies before integration.

- Design venting paths and allocate space for VOC sensors.

- Secure long‑lead, space‑qualified suppliers early.

What is the difference between TML and CVCM?

TML measures the total weight loss of a sample during a 24‑hour vacuum bake, while CVCM records only the portion that condenses on a cold surface. Both must stay below the limits set by ASTM E595‑21 for a material to be flight‑qualified.

Can standard commercial electronics be used in a crewed habitat?

Only if they pass a dedicated bake‑out and meet the outgassing limits. In practice, most commercial boards (FR‑4) exceed the CVCM threshold, so designers switch to space‑grade polyimide PCBs or encapsulate components in ceramics.

How often should VOC sensors be calibrated on the ISS or similar habitats?

NASA recommends a full calibration every 180 days, with a quick check before each crew rotation. Sensors that detect down to 10 ppb can alert crew to emerging contamination before it reaches health‑impact levels.

Is vacuum baking the only way to reduce offgassing?

Baking is the most effective method, cutting VOC release by up to 50 %. Other tactics-such as selecting low‑outgassing adhesives, using ceramic substrates, and maintaining cleanroom assembly-complement baking but rarely replace it entirely.

What emerging material technologies could lower offgassing further?

Researchers are experimenting with graphene‑based coatings and nano‑engineered ceramics that bind volatile molecules, effectively acting as built‑in scrubbers. Early tests show TML values under 0.1 % and CVCM under 0.01 %.

8 Responses

Off‑gassing is a hidden hazard in any closed‑loop habitat and the data you shared makes it crystal clear why early material screening is non‑negotiable. Keeping the TML and CVCM under the ASTM limits saves a lot of downstream cleaning work. A quick pull from NASA’s outgassing database early in the design phase can flag problematic parts before CAD even starts. Pair that with a Z‑score ranking and you balance structural performance with contamination control. It’s a solid workflow for any crewed module.

Oh sure, let’s just ignore the vacuum bake because who needs a half‑hour coffee break when you can risk a cabin full of formaldehyde? Those standard FR‑4 boards love to spew VOCs like it’s a hobby. Good thing the guide tells us to swap them out for polyimide – otherwise we’d have a kitchen‑scented space station. The numbers don’t lie, even a cheeky bake‑out can slash emissions by half.

In the context of life‑support systems material outgassing represents a quantifiable risk factor that must be mitigated through strict testing protocols. ASTM E595‑21 provides clear thresholds for total mass loss and collected volatile condensable materials ensuring compatibility with closed environments. The database of over five thousand entries serves as a valuable reference for engineers seeking compliant components. Selecting metals or ceramics often satisfies both criteria without additional processing steps. When polymeric materials are required, space‑qualified formulations and bake‑out procedures become essential. Continuous monitoring with ppb‑level sensors completes the mitigation strategy.

Plan your long‑lead‑time suppliers now to avoid schedule delays.

This guide hits all the right notes – early heritage reviews, bake‑out steps, and real‑time VOC monitoring are exactly what crews need for a healthy habitat. Remember to calibrate the sensors every six months as recommended, it’s a small habit that prevents big problems. The checklist at the end is a handy reference for any design team.

Let me tell you why using cheap commercial FR‑4 is a spectacularly reckless move – it’s basically inviting a toxic cloud to crash party in your life‑support loop. Those boards burst out formaldehyde like a bad fireworks show, and you’ll waste months chasing clogged filters while the crew complains about eye irritation. If you think a half‑baked bake‑out will magically fix it, you’re living in a delusional fantasy. The only sane path is to spend the cash on space‑grade polyimide or ceramic encapsulated parts, even if it hurts the budget. Anything less is a recipe for disaster and a spectacular loss of credibility.

In the silent void of orbit, every molecule that escapes from a surface carries a story of human ambition and hidden peril. The humble volatile organic compound, unseen and inert to the naked eye, becomes a whispering phantom that can erode the very fabric of a crew’s wellbeing. When we loft a habitat into the cosmos, we are not merely launching hardware, we are sealing a micro‑ecology where air quality is the thin line between life and oblivion. Off‑gassing, therefore, is not a technical footnote; it is the subtle antagonist in the theater of space exploration. The ASTM E595‑21 limits of TML under one percent and CVCM under a tenth of a percent read like a moral covenant, demanding that we respect the sanctity of the breath we share. Metals and ceramics, with their stoic composure, stand as guardians that honor this covenant, shedding scarcely a whisper of vapor. Polyimide‑based polymers, when carefully formulated, join this choir of low‑emission allies, while standard plastics roar like untamed beasts, spewing fumes that would sour the finest wine. The Z‑transformation method, in its elegance, balances the raw strength of a material against its tendency to poison the air, reminding us that engineering is an art of compromise. Yet, beyond numbers, there lies a philosophical truth: every decision we make on this metallic sphere echoes through the breathable atmosphere we entrust to our fellow travelers. A careless choice, a shortcut in procurement, becomes a betrayal of that trust, a silent sabotage that can manifest as eye irritation, sensor drift, or corrosion of delicate optics. The future we envision, with embedded VOC sensors and self‑healing filtration, is a promise that we must honor today by demanding the highest quality materials. Water sorption, thermal cycling, radiation – these are the hidden dragons that can awaken dormant volatiles long after launch, and only diligent testing can keep them at bay. As designers, we are the custodians of that air, charged with the solemn duty to vet every adhesive, every board, every coating with relentless rigor. Let us therefore approach material selection not as a checklist, but as a ritual of reverence for the invisible breath that sustains us. In this quiet covenant with the cosmos, the true measure of our success will be the purity of the air that fills our habitats, and the silent gratitude of the crews who live within it.

Your poetic framing captures the essence of why material choices matter, and it reinforces the practical steps we must follow. The checklist you highlighted aligns perfectly with our current project milestones, ensuring that each component meets both performance and contamination criteria. By integrating real‑time VOC sensors we can close the feedback loop and act before concentrations become harmful. This proactive stance not only safeguards crew health but also extends the lifespan of critical hardware. With disciplined sourcing and vigilant monitoring, the vision of a pristine orbital home becomes well within reach.