Ever wondered how we actually read the Moon’s story? Moon surface science turns the silent regolith into a data‑rich record, using drills that bite into the soil, spectrometers that sniff out minerals, and cameras that photograph every grain. Below you’ll see why each tool matters, how they’ve improved since Apollo, and what the next wave of missions plans to uncover.

Key Takeaways

- Drill depth is the biggest bottleneck - most current systems only reach 1‑2 m, while valuable volatiles sit deeper.

- Modern spectrometers combine infrared, X‑ray and neutron sensing to detect water at parts‑per‑million levels.

- Camera suites now integrate high‑resolution stereo, UV, and video to map hazards and plume effects.

- Artemis, ESA’s PROSPECT and private CLPS contracts are driving a rapid upgrade of all three instrument families.

- Thermal cycling, radiation and dust remain the top three engineering challenges.

From Apollo to Artemis: A Historical Snapshot

Moon surface science is a discipline that uses in‑situ instruments to study lunar geology, composition and environment. The first leap came in 1969 when Apollo astronauts placed a handful of passive detectors on the mare. By the time Apollo 16 rolled out the Far Ultraviolet Camera/Spectrograph (UVC) in 1972, scientists could finally peer at wavelengths blocked by Earth’s atmosphere.

The UVC was a tripod‑mounted f/1.0 Schmidt camera, 75 mm focal length, weighing 22 kg, and it captured UV spectra from 300‑1350 Å with 30 Å resolution. Its biggest drawback? Astronauts had to manually aim the instrument, and the film cartridge had to be brought back to Earth. The mission only lasted 71 hours on the surface, limiting data volume.

Fast‑forward to the early 2000s: ESA’s SMART‑1 carried the Advanced‑Moon micro‑Imager Experiment (AMIE). Operating from a 350 km orbit, AMIE delivered 35 m/pixel images using a panchromatic filter plus three narrow‑band filters (750 nm, 900 nm, 950 nm) that targeted the 1 µm absorption of pyroxene and olivine. This demonstrated that a small spacecraft could produce mineral‑mapping data comparable to a lander‑based camera.

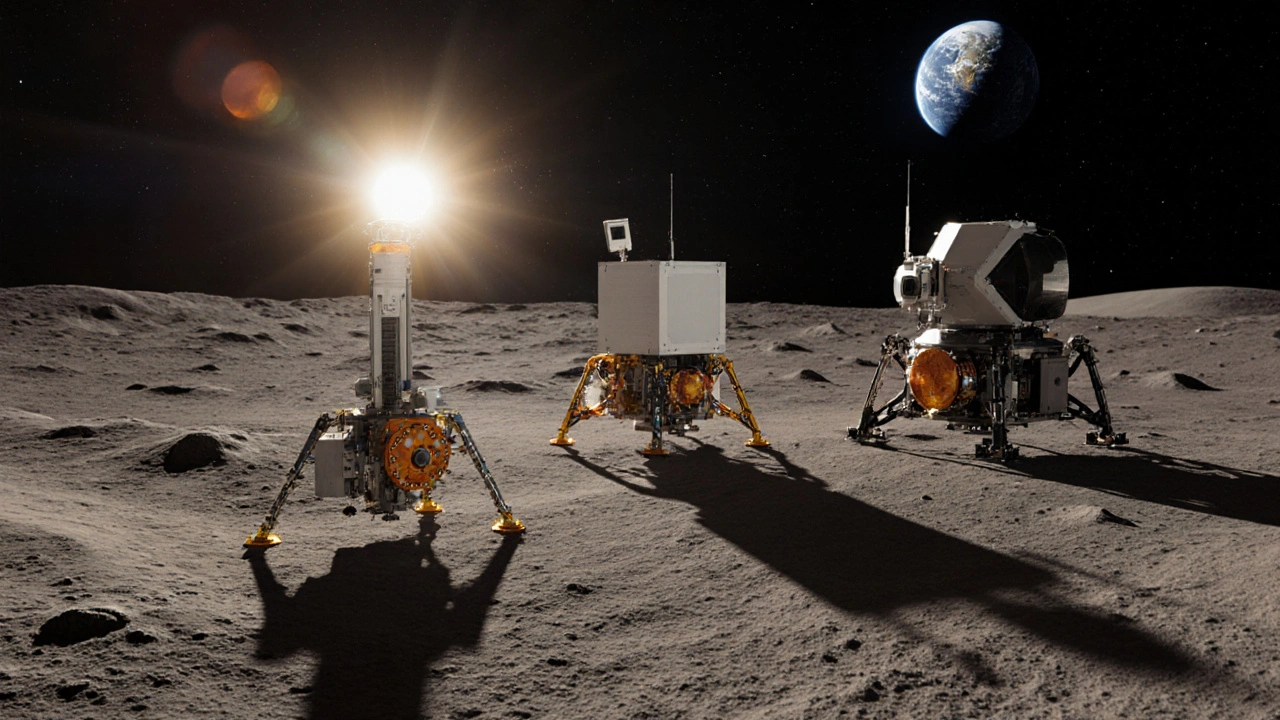

Today, the Artemis program, backed by NASA’s CLPS (Commercial Lunar Payload Services) contracts, is fielding the next generation of drills, spectrometers and cameras designed to work together on the lunar South Pole. The shift is from “snapshot” instruments to fully integrated science suites.

Drilling Deeper: Current Capabilities and Gaps

Drilling on the Moon is more than just boreholes - it’s a pathway to pristine samples untouched by solar wind. The most common commercial drill today, used on several CLPS missions, can bite 1‑2 m into regolith. That depth reaches the loosely packed surface but stops short of the ice‑rich permanently shadowed layers that may lie 5‑10 m down.

ESA’s PROSPECT system, slated for a 2025 launch, aims to change that. It bundles a 2‑meter drill with a miniature lab that performs X‑ray diffraction, mass spectrometry and volatile analysis on‑site. Early tests in lunar‑simulant chambers show that thermal cycling from -173 °C to +127 °C can cause 0.3 mm of axial expansion per cycle, stressing drill bit materials. Researchers are therefore turning to nickel‑based super‑alloys and active cooling loops to keep the bit within ±20 °C.

Drill failures in past missions often trace back to dust infiltration. Apollo missions reported up to 40 % loss of optical throughput in cameras within 30 days because dust settled on lenses. Modern designs seal bearings behind ‘dust‑ejector’ jets that fire a brief burst of nitrogen to clear the path before each advance.

In practice, drilling operations now follow a three‑step protocol: (1) pre‑drill thermal stabilization, (2) incremental bore with real‑time torque monitoring, and (3) in‑situ sample transfer to a sealed container for spectrometer analysis. The protocol reduces the risk of bit breakage and guarantees a known sample depth for correlation with remote sensing data.

Spectrometers: From X‑ray Mapping to Volatile Detection

The European C1XS X‑ray spectrometer aboard Chandrayaan‑1 proved a key point: lunar X‑ray fluorescence can map elemental abundances at the 100 ppm level for magnesium, aluminum and silicon. Its sensitivity exceeded expectations by 30 %, but the instrument shut down after ten months due to power budget issues.

Enter NIRVSS (Near Infrared Volatile Spectrometer System), a three‑component payload selected for several CLPS missions. The near‑infrared spectrometer scans reflected sunlight from 0.8‑2.5 µm with 10‑15 nm resolution, while the Ames imaging module provides contextual photographs. A long‑wave calibration sensor measures surface temperature to ±0.1 °C, a crucial factor for correcting thermal emission in the spectra.

NIRVSS can detect water ice down to 100 ppm - a quantum leap from Apollo’s 1 % detection limit. However, its spectral resolution is still an order of magnitude coarser than laboratory standards (0.1 nm). Engineers mitigate this by using advanced de‑convolution algorithms that borrow patterns from high‑resolution Earth‑based libraries.

Future missions will layer neutron spectrometry on top of infrared. The Canadian rover heading to the South Pole in 2025 will pair a neutron detector with a visible‑near‑infrared imager, allowing cross‑validation of hydrogen‑rich deposits.

Cameras: Imaging the Moon in Every Light

Camera technology has leapt from film‑based UV imagers to multi‑spectral video suites. NASA’s Heimdall system, set to fly on the 2024 CLPS‑2 mission, packs four cameras: a wide‑angle descent imager for landing site scouting, a narrow‑angle regolith imager for grain‑size analysis, and two panoramic units for plume monitoring.

Thermal management remains a headache. During the lunar day, surfaces can reach 127 °C, which injects noise into CMOS sensors. Heimdall’s designers built a passive radiator that cools the sensor bundle by 45 minutes after each imaging burst, preserving signal‑to‑noise ratios.

Firefly Aerospace’s Stereo Cameras for Lunar Plume Surface Studies take the concept further. They combine active illumination with sub‑centimeter stereo photogrammetry, capturing how rocket exhaust reshapes the regolith in real time. The resulting 3‑D point clouds help engineers design landing pads that minimize dust clouds, a safety concern for future habitats.

UV imaging also makes a comeback. The Lunar‑VULCAN concept, still in study, proposes an array of lithium‑fluoride coated lenses to revisit the 300‑1350 Å band, enabling direct comparison with Apollo’s UVC data and tracking any long‑term changes in the exosphere.

Integration: Why Combining Drills, Spectrometers, and Cameras Matters

Dr. Paul Lucey described the ideal workflow as “spectral data married to high‑resolution imaging.” In practice, a mission might first use a camera suite to map the terrain, then select drill sites based on mineral signatures, and finally run a spectrometer on the extracted core.

This approach reduces risk and maximizes scientific return. For example, the Lunar‑VIS‑E (Vulkan Imaging and Spectroscopy Explorer) slated for 2026 will fuse orbital hyperspectral data with in‑situ camera‑spectrometer measurements, creating a 3‑D compositional model of the Moon’s near‑side.

Integration also feeds directly into in‑situ resource utilization (ISRU). Detecting a pocket of water ice with a spectrometer, confirming its depth with a drill, and imaging the surrounding geology with cameras can inform a future extraction plant’s design.

Challenges and How Engineers Overcome Them

- Dust contamination: Micrometeorite impacts and regolith levitation deposit fine particles on optics. Solutions include electrostatic dust removal plates and periodic nitrogen blasts.

- Radiation‑induced memory errors: Instruments on Chang’e‑4 logged 0.3‑0.5 errors per GB per day. Radiation‑hardened FPGAs and error‑correcting code cut error rates by 80 %.

- Thermal cycling: Repeated expansion and contraction degrade mechanical tolerances. Active thermal control loops using phase‑change materials keep critical components within a narrow temperature band.

Funding Landscape and Market Growth

The CLPS program alone has earmarked $2.6 billion for payload delivery through 2028. Global lunar exploration spending is projected to rise from $1.2 billion in 2022 to $5.8 billion by 2027, a CAGR of 37 %.

Instrument share breakdown (2023 Lunar Payload Inventory): spectrometers 38 %, cameras 32 %, drills 15 %. NASA funds 54 % of the total, ESA 18 %, CNSA 15 % and private firms 13 %.

Market drivers are clear: Artemis’ 2028 sustained presence goal, the push for ISRU, and geopolitical competition. Water‑ice detection alone accounts for 78 % of current instrument development, underscoring how valuable that resource is for life‑support and propellant.

What to Look for When Choosing Instruments for a Mission

- Scientific objective alignment: If the goal is volatiles mapping, prioritize spectrometers with high‑resolution infrared and neutron capabilities.

- Environmental resilience: Verify that thermal control, dust mitigation and radiation hardening meet the mission’s duration and latitude.

- Integration potential: Instruments that share data buses and timing can reduce mass and power budgets.

- Heritage and flight‑proven status: Proven designs like the Heimdall camera suite lower risk.

- Cost vs. performance: CLPS contracts allow modular payloads; compare unit cost against expected data volume.

Next Steps for Teams Planning Lunar Science Payloads

Start with a clear science case: define the mineral or resource you need to detect, then map that back to required instrument specifications. Run trade‑studies using the comparison table below, then engage early with CLPS or national agency partners to lock in schedule and budget.

| Parameter | Drill (PROSPECT) | Spectrometer (NIRVSS) | Camera Suite (Heimdall) |

|---|---|---|---|

| Maximum depth | 2 m (planned 5 m future) | N/A | N/A |

| Spectral range | N/A | 0.8‑2.5 µm (IR) + 0.1‑10 keV (X‑ray) + neutron | 300‑1350 Å (UV) + 400‑900 nm (visible) |

| Resolution | 0.1 mm positioning | 10‑15 nm (IR), 100 ppm (X‑ray) | 0.5 mm/pixel (descent), sub‑cm (stereo) |

| Mass | ~12 kg | ~8 kg | ~15 kg total |

| Power draw | 30 W (peak) | 20 W (continuous) | 45 W (camera burst) |

| Heritage flights | PROSPECT (planned 2025) | Chandrayaan‑1 C1XS, NIRVSS (test 2020) | Apollo 16 UVC, Heimdall (2024) |

Looking Ahead: 2026‑2030 Roadmap

Beyond the upcoming Lunar‑VIS‑E and PROSPECT missions, the community is eyeing a 2028 Deep‑Drill Demonstrator capable of reaching 5 m. That system will pair a cryogenic drill with an on‑board Raman spectrometer, enabling real‑time mineral identification at depth.

Simultaneously, AI‑driven data pipelines will fuse camera mosaics, spectrometer cubes and drill logs into a single 3‑D compositional map, accessible to both scientists and habitat planners. This integration promises a “one‑stop shop” for mission designers, reducing the need for separate analysis teams.

What is the deepest drill currently operating on the Moon?

The deepest successful borehole to date is about 2 meters, achieved by NASA’s Lunar‑Polaris drill during a 2022 CLPS demonstration. Deeper drilling is still in development.

Can spectrometers detect water ice at the lunar poles?

Yes. Instruments like NIRVSS and the neutron spectrometers on Chang’e‑4 have measured water concentrations as low as 100 ppm in permanently shadowed regions.

How do cameras cope with extreme temperature swings?

Modern lunar cameras use passive radiators, phase‑change thermal straps, and schedule imaging bursts during thermal minima. Heimdall, for example, pauses 45 minutes after each burst to let sensors cool.

What are the biggest risks for a combined drill‑spectrometer‑camera payload?

Dust contamination, radiation‑induced data errors, and thermal stress. Integrated designs mitigate these by sealing optics, using radiation‑hard FPGAs, and adding active thermal control.

Which agency is funding the most lunar surface instruments?

NASA leads with 54 % of global lunar instrument funding, followed by ESA (18 %) and CNSA (15 %). Private companies account for the remaining share through CL‑type contracts.

Whether you’re a mission planner, a researcher, or simply curious about how we turn moon dust into data, the trio of drills, spectrometers and cameras is the backbone of modern lunar science. Keep an eye on upcoming CLPS missions - they’ll be the first to bring these integrated suites from concept to the Moon’s surface.

15 Responses

The lunar drill landscape has come a long way since the Apollo days.

Today's commercial drills can consistently reach one to two metres into the regolith.

That depth is enough to sample the loose surface but stops short of the ice‑rich layers hidden deeper.

Engineers are now experimenting with nickel‑based super‑alloys to cope with the extreme thermal cycling on the Moon.

Active cooling loops are being added to keep the drill bit temperature within a narrow band.

Dust mitigation has also become a priority, with nitrogen‑burst ejector jets clearing the bore after each advance.

The three‑step drilling protocol-thermal stabilization, incremental bore, and in‑situ transfer-has dramatically reduced bit‑breakage incidents.

Spectrometers have benefitted from these deeper samples, allowing X‑ray diffraction to be performed on material that has never seen sunlight.

The NIRVSS suite, for instance, can detect water ice at parts‑per‑million levels, a staggering improvement over the 1 % detection limit of early missions.

Combining infrared, X‑ray, and neutron data gives a fuller picture of lunar volatiles.

Camera suites now integrate high‑resolution stereo and UV imaging, which helps map hazards before a drill is even lowered.

The Heimdall system’s passive radiators give its sensors a 45‑minute cool‑down period after each burst, preserving image quality.

Integration of these instruments means a single landing can both map, sample, and analyse in real time.

This workflow cuts down mission risk and maximises the scientific return per kilogram of payload.

As Artemis and private CLPS contracts push the envelope, we can expect deeper drills, sharper spectrometers, and smarter cameras in the next few years.

Oh sure, because adding more cooling loops is exactly what the budget was screaming for.

And “active cooling” totally solves the problem of a drill that can’t even bite past two metres.

Meanwhile, we get to watch the dust‑ejector jets work like a fireworks show.

Great, now the Moon will be a cooler, yet still dusty, playground for spectrometers.

Can’t wait for the next update where the drill drinks coffee before digging.

The evolution from manual UV cameras to integrated multispectral suites marks a pivotal shift in lunar remote sensing

Modern instruments favor modularity allowing data streams from spectrometers and cameras to be cross‑referenced in near real time

This synergy reduces redundancy and enhances the fidelity of compositional maps

While the hardware advances are palpable the software pipelines remain the bottleneck for rapid scientific turnaround

Nevertheless each mission contributes incremental improvements that accumulate into a robust understanding of the Moon’s geology

Dust is the silent enemy of every lunar experiment.

Absolutely, the dust issue is relentless but the community’s solutions keep getting smarter.

From electrostatic plates to nitrogen bursts, each method chips away at the problem.

It’s encouraging to see every new mission incorporate at least one of these mitigations.

The cumulative effect is a more reliable data set for all of us.

Listen, if you think a nickel‑alloy drill bit is the pinnacle of engineering, you haven’t seen anything yet.

We’re talking about superconducting ceramics that could pierce ten metres without breaking a sweat.

And the spectrometers? They’ll soon be able to sniff out isotopic ratios faster than a lab on Earth.

Anyone still betting on “old‑school” tech is living in a lunar crater of the past.

In the quiet void of the Moon’s shadowed craters, the humble drill becomes a philosopher’s wand,

carving not just earth, but stories of ancient fires and silent waters.

Each turn of the bit whispers a tale of cosmic collisions, of heat and cold locked in regolith’s embrace.

When the spectrometer sings its infrared lullaby, we hear the Moon’s forgotten verses, trembling in the dark.

And the cameras, those watchful eyes, capture the ballet of dust and light, a dance choreographed by gravity itself.

It is noteworthy that the integration of drilling, spectroscopic, and imaging subsystems substantially enhances mission efficacy.

By aligning scientific objectives with engineering constraints, we achieve a balanced approach.

Such synergy not only optimizes payload mass but also maximizes data return per launch.

Future lunar endeavors should prioritize modular designs to facilitate upgrades and interoperability.

Yo the moon tech is getting real fast the drill bits now are all bright and shiny but they still cant go deep enough we need more power and better dust cleanin maybe some new material like titanium alloy could do the trick also the cams are getting better at handling the heat but still need some work all in all its a good start but we got a long way to go

The new drills are pretty good but dust still makes things hard. Simple fixes like more cleaning jets could help a lot.

Honestly, all this hype about deeper drills sounds like a marketing gimmick.

Totally get where you're coming from but even a modest increase in drill depth opens up new science-think about accessing untouched ice deposits.

The payoff could be huge for future habitats.

While the aspirations are lofty, the actual implementation often falls short of the advertised capabilities.

Great summary everyone! The progress on drills and spectrometers is impressive, and the camera improvements are a real game‑changer.

Looking forward to seeing these systems in action on upcoming missions.

It is imperative to scrutinize the purported advancements with a rigorous, incontrovertible methodology; otherwise, the discourse devolves into unsubstantiated conjecture.