On Earth, gravity is so constant we barely notice it. But in orbit, where astronauts float and coffee drifts in spheres, gravity’s absence doesn’t just change how things move-it changes what things are. Materials behave differently in microgravity. Not just a little. Not just slightly better or worse. Fundamentally. The way crystals grow, how metals solidify, how liquids mix-all of it shifts when you remove the pull of Earth. And that’s not just science fiction. It’s happening right now on the International Space Station, with real-world results that are changing how we make everything from semiconductors to medicine.

Why Microgravity Changes Material Behavior

On Earth, gravity drives convection, sedimentation, and pressure gradients. Hot fluids rise. Heavy particles sink. Liquids settle. These forces are invisible in daily life, but they dominate how materials form at the microscopic level. In microgravity, none of that happens. Without gravity, there’s no buoyancy. No sinking. No rising. No natural layering. That means when you melt metal, cool a crystal, or mix polymers in space, the process is governed only by molecular forces-surface tension, diffusion, thermal gradients. No distractions. That’s why crystal growth in space is so valuable. Germanium and silicon crystals grown on the ISS have 30-50% fewer dislocations than those made on Earth. Dislocations are defects in the crystal lattice that block electrons. Fewer dislocations mean higher electron mobility-up to 22% better. That’s not a small improvement. That’s the difference between a chip that works and one that overheats. Even something as simple as soldering changes. On Earth, when solder melts, convection currents swirl the molten metal unevenly. In space, those currents vanish. The result? Solder joints with 40% more uniform grain structures. Nano-mechanical tests show these space-made joints are 27% stronger. That matters for satellites, space stations, and future lunar bases where a single failed connection can cost millions-or lives.ZBLAN Fiber: The First Big Commercial Win

Of all the materials being tested in space, ZBLAN fluoride-based optical fiber is the standout success. On Earth, gravity causes tiny crystals to form inside the fiber during manufacturing. These crystals scatter light, increasing signal loss. In microgravity, those crystals don’t form. The result? Fibers with 100 times less signal loss than standard silica fibers. That’s not theoretical. It’s been proven in multiple ISS experiments. Made In Space, a company specializing in space manufacturing, improved their ZBLAN production yield from just 22% usable fiber in 2019 to 100% in 2022. They didn’t change the chemistry. They just removed gravity. Now, Redwire Space has launched a dedicated facility designed to produce 500 grams of ZBLAN fiber per year. First commercial shipments are expected in early 2024. This isn’t a lab curiosity. It’s a product. Why hasn’t this replaced Earth-based fiber? Cost. Launching one kilogram to the ISS costs about $1.2 million. ZBLAN fiber is so valuable-used in high-speed medical imaging, defense systems, and deep-space communications-that it justifies the price. For most consumer electronics? No. But for niche, high-value applications? Absolutely.Metals, Cement, and the Strange World of Space Manufacturing

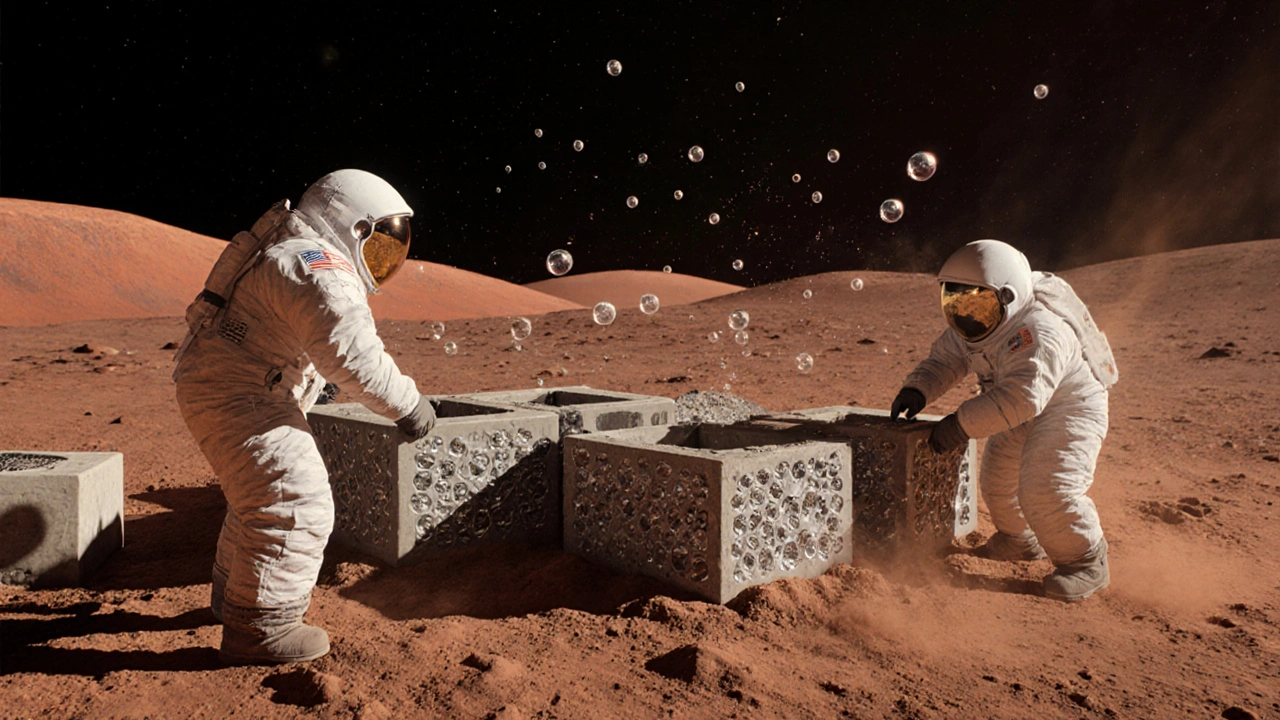

NASA’s Microgravity Investigation of Cement Solidification (MICS) showed something unexpected. When cement is mixed and hardened in space, it forms large, evenly distributed air bubbles. On Earth, bubbles rise and cluster near the top. In microgravity, they spread out uniformly. That means space-made cement could be lighter, more insulating, and stronger under pressure. That’s critical for building habitats on the Moon or Mars, where every gram of material matters. Metal alloys behave differently too. In a NASA experiment, solid tin particles were mixed into a lead-tin liquid. On Earth, the denser tin sank in under 2.3 minutes, creating uneven mixes. In space? The particles stayed evenly distributed. Uniformity improved by 85%. That kind of control could lead to stronger, lighter alloys for aerospace-materials that don’t crack under stress or fatigue over time. Even polymers change. Studies show membrane fluidity increases by 15-20% in microgravity. That affects everything from drug delivery systems to artificial cells. Meanwhile, hypergravity (simulated centrifuges) stiffens those same membranes by 22-25%. This isn’t just about space. It’s helping scientists understand how cells respond to pressure on Earth-like in deep-sea diving or high-G fighter jets.

What Doesn’t Work in Space?

Microgravity isn’t magic. It doesn’t improve everything. For materials where quantum effects dominate at the atomic level-like superconductors or certain nanomaterials-gravity’s absence makes little difference. The forces at play are too small to be affected by buoyancy or sedimentation. And scaling is a nightmare. ISS experiments are limited to samples smaller than 10 cm³. Industrial Earth-based production handles cubic meters. You can’t make a car engine block in space. You can’t pour a bridge foundation. The economics only work for tiny, ultra-high-value products: specialty fibers, pure pharmaceutical crystals, precision alloys. There’s also the issue of control. In one study, 35% of powder-based experiments failed because electrostatic forces caused particles to stick to container walls. In microgravity, there’s no gravity to pull them down. So they float-and cling. That’s something you can’t predict from Earth labs.The Road to Space Manufacturing: Harder Than It Looks

Getting an experiment to the ISS isn’t like ordering a kit online. It takes 3-5 years. First, you submit a proposal. Acceptance rates dropped from 24.3% in 2019 to 18.7% in 2022. More people want in. Competition is fierce. Then comes hardware development. Everything must meet NASA-STD-6001, the strictest flammability and safety standard in aerospace. A simple fluid cell might take 18 months to design, test, and certify. Many researchers underestimate how much they need to know about spacecraft systems. 73% of first-timers hit major delays because they didn’t account for thermal control, vibration, or power limits. Even after launch, results aren’t guaranteed. Dr. Aleksandra Radlińska’s cement team ran three separate ISS missions between 2019 and 2022 just to get the containment right. One leak. One wrong temperature. One timing error-and the whole experiment fails. And then there’s the data. NASA’s microgravity handbook scores 4.2 out of 5 for completeness. But commercial guides from the ISS National Lab? Only 2.8. If you’re a startup trying to break into this space, you’re often flying blind.

Who’s Doing This-and Why?

There are now 147 active research groups worldwide working on microgravity materials. Academic teams take an average of 2.3 years to publish results. Commercial firms like Made In Space and Redwire do it in 1.7. Why? They’re building products, not just papers. The market is shifting. In 2015, NASA funded 78% of microgravity materials research. Today, commercial partners fund 63%. That’s a huge change. Companies aren’t just renting space on the ISS-they’re investing in it. The space manufacturing market is projected to hit $14.8 billion by 2030, driven almost entirely by ZBLAN fiber and pharmaceutical crystal growth. Pharmaceutical companies are already using microgravity data to improve drug manufacturing. 41 firms report 19% higher yields for complex protein crystals grown in space. Those crystals are harder to form on Earth because gravity distorts their natural shape. In space, they form perfectly. That means better, more effective drugs.The Future: More Stations, Lower Costs, Bigger Potential

The ISS won’t last forever. But new platforms are coming. Axiom Space is building a commercial station set to dock with the ISS in the next few years. By 2030, it could cut experiment costs by 65%. That’s a game-changer. NASA’s 2024 budget allocates $187 million specifically for microgravity materials research-with a focus on lunar regolith processing. They’re not just studying space materials. They’re learning how to build with Moon dust. The European Space Agency’s MiPS study found that in microgravity, particles grow more predictably through a process called Ostwald Ripening. Accuracy improved from 87.4% on Earth to 99.2% in space. That kind of precision could revolutionize nanotechnology. But there’s a limit. Launch costs won’t drop enough to make bulk manufacturing viable before 2040. Microgravity won’t replace Earth factories. But it will create new ones-small, specialized, high-value. Think of it like a luxury watchmaker: you don’t make thousands of watches in space. You make a few, perfect ones.What We Still Don’t Know

Despite all the data, we’re still learning. Dr. Kohn’s team found that membranes change in microgravity-but they don’t know why. Is the membrane expanding? Are molecules moving farther apart? The molecular mechanism is still hidden. Dr. Furst says microgravity helps explain snowflake formation. Dr. Sahakian says it reveals the true nature of material structure. Dr. Glicksman warns we’re seeing patterns, but we don’t yet know if they’re natural or just noise. That’s the real power of microgravity. It doesn’t just give us better materials. It forces us to ask better questions. It strips away the noise of Earth and lets us see what’s really happening at the molecular level. We’re not just making things in space. We’re learning how to make them better-on Earth, too.Why do materials behave differently in microgravity?

On Earth, gravity causes convection, sedimentation, and pressure differences that interfere with how materials form. In microgravity, these forces disappear. Without them, materials form based only on molecular interactions-surface tension, diffusion, and thermal gradients. This leads to purer crystals, more uniform metal alloys, and smoother phase separations that are impossible to achieve on Earth.

What’s the most successful material made in space so far?

ZBLAN fluoride optical fiber is the most commercially successful. Ground-based ZBLAN fibers suffer from 92% more crystallization defects due to gravity-induced convection. In space, those defects vanish, resulting in fibers with 100 times less signal loss. Companies like Redwire Space are now producing them commercially, with first shipments expected in 2024.

Can we make large-scale products in space like cars or buildings?

No. Current space manufacturing is limited to tiny samples-under 10 cm³-due to spacecraft size and safety limits. Industrial-scale production requires cubic meters of space and massive energy inputs, which aren’t feasible on orbit. Microgravity manufacturing is only economically viable for high-value, low-volume products like optical fibers, pharmaceutical crystals, and precision alloys.

How much does it cost to run a materials experiment in space?

Launching one kilogram to the ISS costs about $1.2 million. But the total cost of a single experiment-including design, testing, certification, and operations-can reach $5-10 million. Most researchers spend 3-5 years from proposal to results. Only high-value applications like ZBLAN fiber or pharmaceutical crystals justify this expense.

Is microgravity research only useful for space applications?

No. In fact, most of the value is on Earth. Microgravity experiments reveal the true behavior of materials without gravity’s interference. This helps improve drug manufacturing, semiconductor design, metal alloys, and even cement formulations. Pharmaceutical companies use space-grown crystals to boost drug yields by 19%. Semiconductor makers use space-grown crystals to improve chip performance.

What are the biggest challenges in space materials research?

The biggest challenges are: (1) high cost and long lead times (3-5 years per experiment), (2) difficulty in scaling sample size, (3) unexpected electrostatic effects that cause 35% of powder experiments to fail, and (4) lack of clear commercial guidelines. Many researchers underestimate how much they need to know about spacecraft systems and safety standards.

12 Responses

Just read this and had to say-space-made ZBLAN fiber is straight-up wild. I work in telecom, and the idea of 100x less signal loss? That’s not just an upgrade, that’s a revolution. And the fact that it’s already shipping in 2024? Mind blown. We’re not just sending stuff to space-we’re outsourcing precision manufacturing to orbit. Crazy to think we used to think space was just for flags and footprints.

So let me get this straight-we’re spending $1.2M per kilo to make fiber that’s better than Earth’s… so we can sell it to NASA and the Pentagon? Meanwhile, my WiFi still drops when the cat walks by. Cool. Cool cool cool. 🙃

Man, I didn’t even know cement acted different in space. The bubbles being even? That’s kinda beautiful. Like, imagine building a lunar base with space-cement-lighter, stronger, no weak spots. We’re basically learning how to be space carpenters now. And honestly? I’m here for it. Even if my brain hurts trying to picture it.

Let’s be real-microgravity isn’t magic, it’s just a controlled environment where you remove the dominant noise factor. Gravity’s been the silent third variable in every material science experiment since the 1800s. Now we’re finally isolating the real physics. The 22% electron mobility boost? That’s not ‘better chips,’ that’s Moore’s Law with training wheels taken off. And yes, the cost is insane-but when you’re making quantum sensors or protein crystals for cancer drugs, you don’t care about the price tag. You care about the outcome. That’s the difference between research and product.

Ugh. Another ‘space is magic’ article. Let me guess-someone forgot that surface tension still exists in microgravity, and that’s what’s *actually* controlling everything. You didn’t remove gravity, you just replaced it with capillary forces. And ‘100x less signal loss’? That’s not even a real number unless you specify wavelength, temperature, and polarization. Also, ‘ZBLAN fiber is commercially viable’? Bro, you’re selling a 500g/year factory like it’s Apple. It’s a lab experiment with a PR team. And don’t get me started on ‘pharmaceutical crystals’-you think the FDA approves space-grown proteins without terrestrial validation? Please. It’s all just hype wrapped in NASA jargon.

So we’re spending billions to make better fiber while people are sleeping in their cars? This is why America’s doomed. We’re building luxury space watches while the roads crumble. You think Elon’s gonna fix your insulin with ZBLAN? Nah. He’s gonna sell you a subscription to ‘Space Fiber Premium’ and charge you $99/month. This isn’t progress. It’s capitalism with a spacesuit.

When I first heard about microgravity material science, I thought it was just academic curiosity. But reading this, I realized something deeper-it’s not just about making things better in space, it’s about understanding what we’ve been missing all along. On Earth, we’ve been looking at materials through a fog of gravity. We thought we knew how crystals formed, how metals cooled, how fluids mixed. But we were only seeing half the picture. In space, we see the truth. And that truth? It’s not just useful for satellites or lunar bases. It’s changing how we design drugs, how we build better batteries, how we make electronics that don’t overheat. It’s like we’ve been colorblind, and now we’re seeing in full spectrum. And honestly? That’s more profound than any moon landing.

Oh honey, you think this is wild? Wait till you hear about the time a NASA scientist tried to mix paint in zero-G and it turned into a glittery, sticky ghost that clung to the walls for three days. No joke. Electrostatic forces are the real villains here-particles floating like tiny space ghosts, refusing to obey physics as we know it. And don’t even get me started on how some alloys just… *decide* to form weird shapes in orbit, like they’re moon-dancing. This isn’t science. It’s alchemy with a budget. But damn, it’s beautiful alchemy.

Can we talk about how insane it is that we’re using space to understand *cells*? I mean, if membranes get 15-20% more fluid in microgravity, that’s not just about drug delivery-it’s about how life itself responds to environment. Are we learning how to make better medicine? Or are we learning how to make better humans? I don’t know. But I’m obsessed. This isn’t just materials science. It’s molecular anthropology.

Who’s really funding this? NASA? Or is it just another DARPA black budget project to weaponize space fiber? Because if they can make a signal loss-free fiber, they can also make a signal that can’t be jammed. Or tracked. Or intercepted. And if they’re making stronger alloys for satellites? What’s the next step? Orbital weapons? This isn’t about science. It’s about control. And you’re all just cheerleading the machine.

It’s so irresponsible to celebrate space manufacturing without addressing the environmental cost. Launching rockets dumps tons of soot into the stratosphere. We’re trading Earth’s health for a few perfect crystals. And who benefits? Billionaires. Not you. Not me. Not the kids who’ll inherit a ruined atmosphere. This isn’t innovation-it’s arrogance dressed up as science. We should be fixing things here, not escaping to orbit to make fancy glass.

Love the passion, Sheila-but you’re missing the point. The rockets are already flying. The damage is done. The question isn’t ‘should we do this?’ It’s ‘how do we do it better?’ And if we can use space to make medicine that saves lives on Earth, or cement that lets us build on Mars without hauling it from here-that’s not arrogance. That’s adaptation. We’re not escaping. We’re expanding. And honestly? If we can make a better drug because we floated a crystal for 60 days, that’s worth the carbon cost. Just sayin’.