Getting water out of Mars soil is the linchpin for any crewed mission. Without a reliable source of H₂O, astronauts can’t drink, make oxygen, or fuel rockets. This article unpacks the two biggest challenges - how deep we have to drill and which heating method actually pulls the water out. By the end you’ll know the trade‑offs, performance numbers, and where the technology sits on the road to flight.

Quick Takeaways

- Martian regolith can hold 2‑20 % water by mass depending on mineral type.

- Drilling to 30 cm depth costs ~150 W; deeper penetration needs more power and specialized scoops.

- Microwave heating offers the highest energy efficiency (≈25 % better than resistive heating) but adds system mass.

- CO₂‑based extraction reuses the thin Martian atmosphere, reducing consumables but cuts extraction rate by ~40 % in perchlorate‑rich soils.

- Subcritical water extraction recovers up to 95 % of bound water but requires high‑pressure vessels and ~35 % more energy.

Why Mars water extraction matters

Martian Regolith Water Extraction is the process of pulling water from the soil and rocks on Mars using in‑situ resource utilization (ISRU) techniques. The water can be split into oxygen for breathing and hydrogen for methane fuel, slashing launch mass by up to 80 % compared with hauling everything from Earth. NASA’s TechPort project #8856 estimates that extracting 1 kg of water needs only 10‑20 % of the mass we’d otherwise launch.

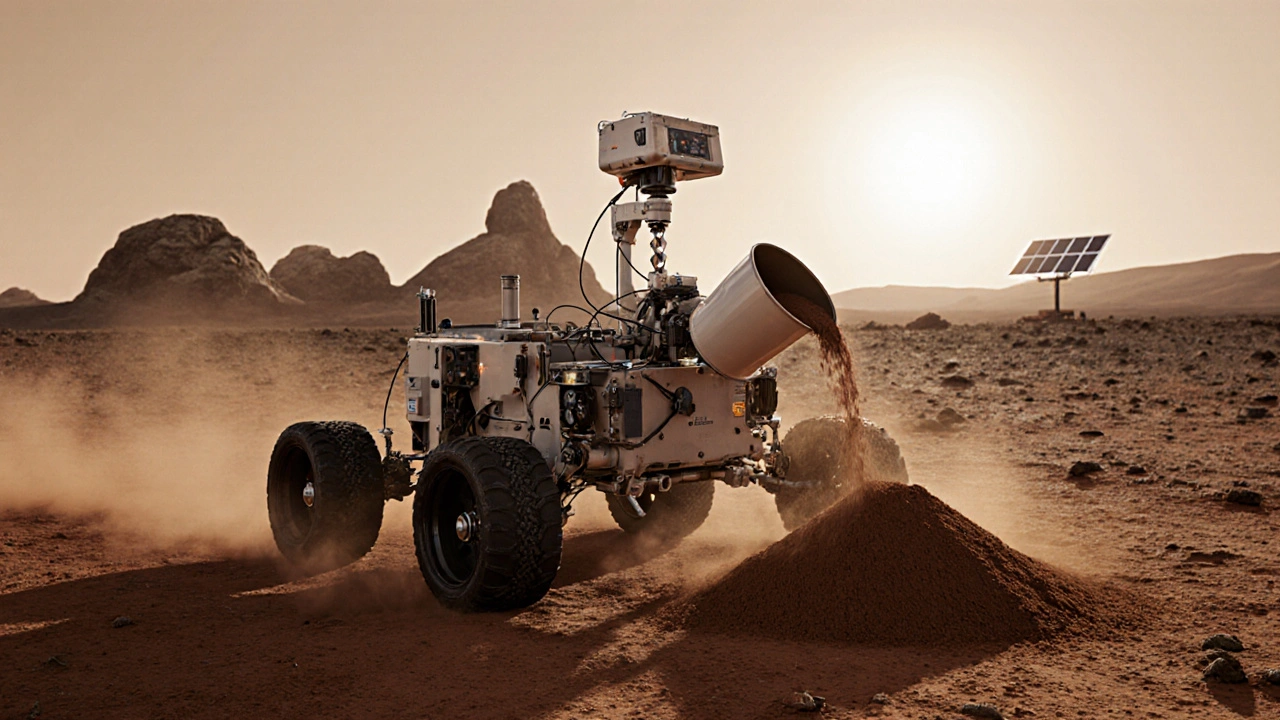

Drilling into Martian soil: how deep and how hard?

Regolith isn’t a uniform sand‑box. It ranges from loose dust to cemented sulfates. The most promising extraction depths sit around 20‑40 cm where hydrated minerals like gypsum, epsomite, and perchlorates are concentrated.

- Power demand: The Cratos excavator (GRC, 2015) used 150 W to reach 30 cm in simulated JSC‑1A regolith.

- Throughput: The Bucketdrum excavator (KSC, 2017) processed 10 kg of material per batch, delivering about 5 kg/hr of regolith to the extraction unit.

- Force required: Vacuum‑chamber tests showed a per‑area force of 2.3 N/mm² to overcome the lack of atmospheric pressure, about 40 % higher than Earth‑analog soil.

Designers therefore favor low‑mass, low‑speed drills with torque‑control algorithms that can adapt to variable cohesion. A common architecture couples a rotary‑drill head with a bucket‑style collection drum, letting the system pause, dump, and reposition without a full‑scale rover arm.

Heating techniques - the core of water release

Once the soil is in a processing chamber, heat does the heavy lifting. Three methods dominate current research:

| Technique | Typical Extraction Rate (kg/hr) | Energy Efficiency* (relative) | Key Advantages | Major Limitations |

|---|---|---|---|---|

| Microwave Heating | 0.15 (JFEET MARCO POLO) - up to 0.5 in later tests | 9.2/10 (≈30 % better than resistive) | Selective heating of water‑bearing minerals; low bulk‑soil heating loss. | Complex power‑management; adds ~18 % mass. |

| CO₂‑Based Extraction (MRWE) | 1 kg per 33 kg regolith (theoretical) | ≈0.6 of microwave efficiency | Uses abundant Mars CO₂; no Earth‑supplied fluids. | 40 % slower in perchlorate‑rich soil; large heat exchangers. |

| Subcritical Water Extraction (SCWE) | 0.85‑0.95 kg per kg of hydrated mineral | ≈0.7 of microwave; higher absolute energy (15‑25 kWh/kg). | Highest water recovery; works on bound water up to 374 °C. | Requires high‑pressure vessel (3‑22 MPa); adds ~22 kg mass. |

*Relative to a baseline resistive oven; values from NASA, JPL, and Caltech assessments (2018‑2022).

Microwave heating - the near‑term favorite

The JPL team’s MARCO POLO (Microwave‑Assisted Process for CO₂‑free) system focuses a 2.45 GHz field directly into the regolith column. Because water molecules rotate with the field, they heat up while the surrounding rock stays cooler. Tests on desert simulants showed 0.15 kg/hr extraction from 3 % water material, scaling to 0.5 kg/hr in the 2021 Mojave field test after power‑up to 1.2 kW.

Key performance notes:

- Efficiency score: 9.2/10 (MSFC 2018).

- Mass: ≈50 kg for the full unit, 18 % heavier than a simple thermal oven.

- Power: 1.2 kW continuous; nighttime operation demands ≥30 % battery capacity.

- Perchlorate impact: extraction drops 32 % when soil >0.5 % perchlorates.

Dr. Philip Metzger (UCF) calls it the “most viable near‑term solution” but warns that reliable power storage for dust‑storm nights remains a hurdle.

CO₂‑based extraction - leveraging the thin atmosphere

In the MRWE concept, a stream of CO₂ from the Martian air is heated to 800 °C using solar collectors or waste heat from a nuclear generator. The hot gas then passes through a bed of regolith, vaporizing water which is later condensed.

Advantages are obvious: no need to transport liquid water or other processing fluids, and the CO₂ is essentially free. However, laboratory sims (KSC 2020) reveal a ≈40 % slowdown in perchlorate‑rich soils, which dominate many mid‑latitude sites.

System specs (NASA TechPort #8856):

- Mass: ~60 kg (including heat exchangers).

- Power: 1.5 kW solar‑array with 12 m² area for 1 kg/day production.

- TRL: 6 as of 2023, ready for integrated flight test.

Dr. Kris Zacny of Honeybee Robotics emphasizes that the approach shines when paired with a hab‑module’s waste‑heat loop, turning a by‑product into a resource.

Subcritical water extraction - squeezing out every drop

SCWE runs water at 100‑374 °C under 3‑22 MPa pressure. The pressurized fluid penetrates mineral lattices, breaking hydrogen bonds and releasing tightly bound water. JPL’s 2018 study showed 85‑95 % extraction from clay minerals in just 15‑30 minutes.

Drawbacks are the high‑pressure vessel and the extra energy needed to pump water to several MPa. Caltech’s KISS assessment tallied an additional 22 kg of hardware, pushing the system’s total mass toward 100 kg for a 1 kg/hr output.

Nonetheless, if a mission targets gypsum‑rich sites (15‑20 % water), SCWE could cut the amount of regolith that needs to be excavated by up to 60 % compared with ice‑sublimation methods, a point highlighted by Dr. Joel S. Levine.

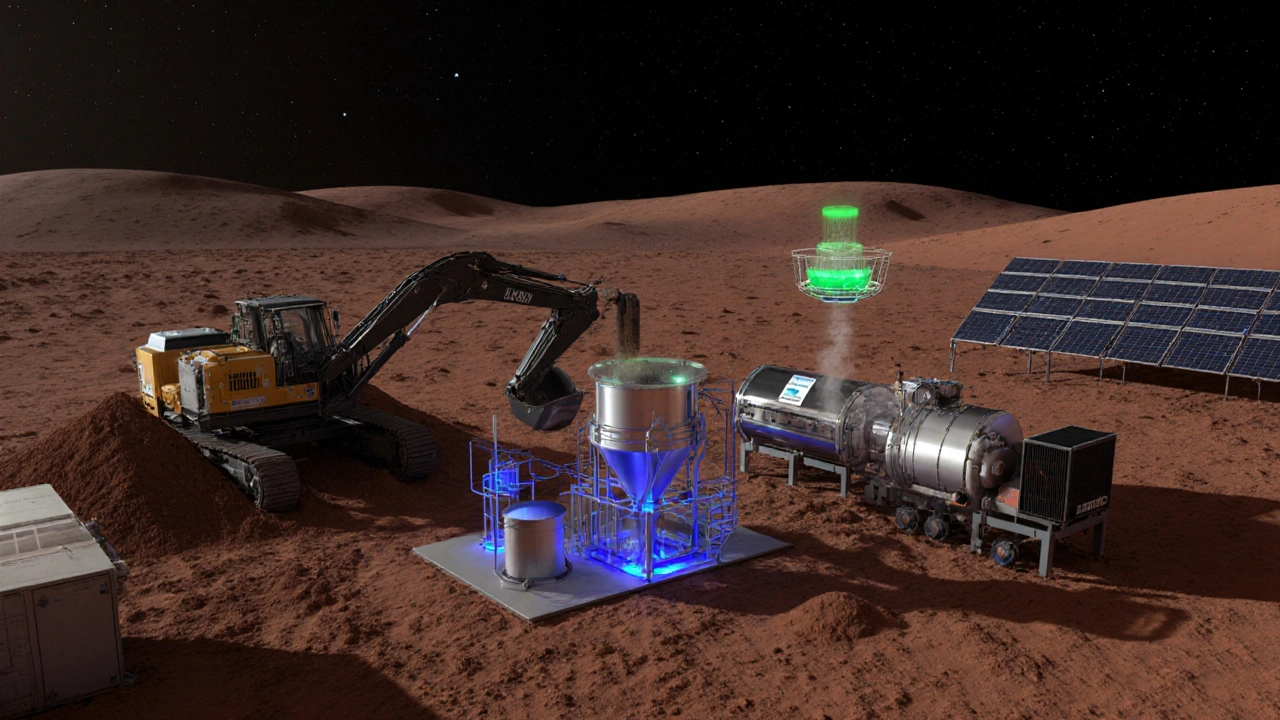

Putting it all together - system architectures

Most design studies now propose a hybrid architecture:

- Excavation unit (e.g., Bucketdrum) shovels regolith into a hopper.

- Pre‑screening uses a mini‑spectrometer to flag high‑water minerals.

- Primary heating applies microwave pulses to bulk material.

- Secondary stage (optional) runs the hot CO₂ stream or SCWE loop for leftover bound water.

- Condensation & storage captures vapor in cryogenic tanks for later electrolysis.

This layered approach maximizes extraction yield while allowing the mission to switch techniques if the local geology changes. The ESA MELISSA program already demonstrated a 0.8 kg/hr microwave‑SCWE combo in 2022.

Current status and roadmap to flight

NASA’s 2023 ISRU roadmap earmarks water extraction as Tier 1. Funding jumped to $37.5 M in FY 2023, pushing three technology lines to TRL 6‑7 by 2027:

- Microwave (JPL) - target 2026 flight‑ready.

- CO₂‑based (KSC/Honeybee) - target 2027.

- Subcritical water (JSC) - target 2028.

The upcoming Mars Sample Return launch window (2026) may carry a small‑scale demo payload, possibly a 0.1 kg/hr microwave unit, to finally prove the concept on the Red Planet.

Key challenges still to solve

Energy efficiency remains the bottleneck. Current systems need 15‑25 kWh per kg of water, while the National Academies recommend ≤5 kWh/kg for sustainable operations. Researchers are exploring:

- Hybrid solar‑nuclear power hybrids to flatten daytime/nighttime gaps.

- Advanced dielectric materials that focus microwaves more tightly, cutting power by ~20 %.

- In‑situ mineral identification using Raman spectroscopy to target the richest beds first.

Addressing these will turn water extraction from a scientific experiment into a workhorse for the first Mars base.

What percent of Martian regolith is water?

Most basaltic soil contains 1‑3 % water by mass, but hydrated sulfates like gypsum or epsomite can hold 5‑20 % water, dramatically reducing the amount of material that must be processed.

Which heating method is most energy‑efficient?

Microwave heating scores highest in lab tests, delivering about 30 % better energy efficiency than resistive ovens. However, the overall system weight and power‑management complexity can offset some gains.

Can a single system handle both drilling and heating?

Hybrid concepts exist, but most designs separate excavation (drill or bucket) from processing to keep each subsystem optimized. Integration usually happens at the hopper stage.

What are the mass penalties for each technique?

Microwave units weigh ~50 kg, CO₂‑based systems ~60 kg (including heat exchangers), and subcritical water kits can exceed 90 kg because of pressure vessels and pumps.

When might we see the first operational water extractor on Mars?

A flight‑demo is slated for the 2026 Mars Sample Return mission. If that succeeds, a full‑scale extraction plant could be part of the 2031 ISA (International Space Architecture) crewed outpost.

9 Responses

The water on Mars is a ticking time bomb waiting to explode!

While the allure of in‑situ resource utilization captivates the collective imagination, the practicalities demand a rigorous appraisal of energy budgets, mass penalties, and operational contingencies. Microwave heating, despite its superior thermodynamic efficiency, imposes a considerable mass overhead that may offset its gains in extraction rate. Conversely, CO₂‑based extraction leverages a planetary constituent yet suffers a notable slowdown in perchlorate‑rich regolith. The engineering community must therefore interrogate not merely the nominal extraction figures but also the integrative system architectures that reconcile power availability with mission timelines.

They don’t want us to know the real cost of these water‑miners. All the “high‑tech” hype hides a massive energy sink. The agencies are feeding us a narrative of sustainability while the power grid on Mars stays a fantasy. Wake up, the dust storms will kill any half‑baked system that can’t survive nights. This isn’t science, it’s a money‑laundering scheme for bureaucrats. Stop the spin and demand transparent audits.

In contemplating the multifarious avenues by which aqueous volatiles may be liberated from the Martian substratum, one is immediately struck by the sheer variegation of mineralogical contexts that govern hydration dynamics.

The hygroscopic proclivities of sulfates such as gypsum and epsomite, for instance, confer a markedly elevated water‑bearing capacity, thereby rendering shallower excavation depths ostensibly sufficient.

Conversely, the more recalcitrant silicate matrices, entrenched within basaltic agglomerations, necessitate a more invasive penetration to access the latent bound water.

It is within this dialectic of depth versus mineralogy that the engineering paradox emerges, compelling designers to balance the energetic exigencies of drilling against the temporal constraints of extraction.

Microwave irradiation, as elucidated by recent JPL trials, capitalizes upon the dielectric loss factor of hydrated minerals, effecting selective volumetric heating whilst sparing the surrounding regolith.

Such selectivity not only curtails extraneous thermal losses but also attenuates the requisite power envelope, a consideration of paramount import given the vicissitudes of solar insolation on the Martian surface.

The CO₂‑based methodology, by contrast, exploits the ubiquitous planetary atmosphere as a carrier gas, allowing for convective heat transfer and subsequent vaporization of moisture.

While laudable in its frugality of consumables, this approach is encumbered by a pronounced decrement in extraction velocity when confronted with perchlorate‑laden terrains.

Subcritical water extraction, though imposing a substantial mass penalty owing to the requisite high‑pressure vessels, offers an unparalleled recovery efficiency, approaching the theoretical zenith of bound‑water liberation.

The thermodynamic trade‑off, however, manifests in an elevated kWh‑per‑kilogram metric that may prove prohibitive in the context of finite power reservoirs.

Hybrid architectures, therefore, present an attractive compromise, wherein an initial microwave pulse desorbs the bulk of free water, followed by a secondary SCWE stage that extracts the recalcitrant fraction.

Such a stratified regimen not only optimizes overall yield but also distributes the thermal load across disparate subsystems, thereby mitigating peak power demands.

Operational considerations further dictate the incorporation of in‑situ spectroscopic diagnostics, enabling real‑time identification of hydration hotspots and adaptive modulation of processing parameters.

From a logistical perspective, the mass and volume budgets of each subsystem must be meticulously reconciled with the vehicle’s payload envelope and launch vehicle capabilities.

In summation, the selection of an extraction paradigm is inexorably linked to site‑specific geochemistry, available power infrastructure, and mission duration.

Future experimental campaigns on analog terrains, complemented by orbital reconnaissance, will undoubtedly refine these trade‑offs and usher in a new epoch of sustainable Martian habitation.

I appreciate the thorough synthesis; the trade‑offs are clearly delineated.

The real agenda behind these ISRU projects is to secure a planetary monopoly on water resources the elites will hoard for off‑world colonies while we remain grounded in scarcity

Hey folks, I think a combined microwave‑CO₂ setup could give us the best of both worlds – fast extraction early on and a reliable fallback when the sun dips.

lol i cant believe how crazy the regolith is its like sand and rock mixed together but with hidden water its wild

Honestly, it is utterly unacceptable, that we would prioritize expediency over ethical stewardship, of a planetary environment that we barely comprehend, and that we would overlook the profound responsibility we bear, as interplanetary explorers, to preserve the sanctity of extraterrestrial resources!