Imagine trying to see a candle flame from 1,000 miles away. That’s what astronomers face when observing distant galaxies in infrared light. The problem isn’t just distance-it’s heat. Every sensor, every wire, every bit of metal in a space telescope glows with its own warmth, drowning out the faint infrared signals from stars and planets billions of years old. The only way to fix this is to cool the detectors down to temperatures colder than anything naturally found on Earth. That’s where cryostats and heat pipes come in.

Why Cold Is Non-Negotiable

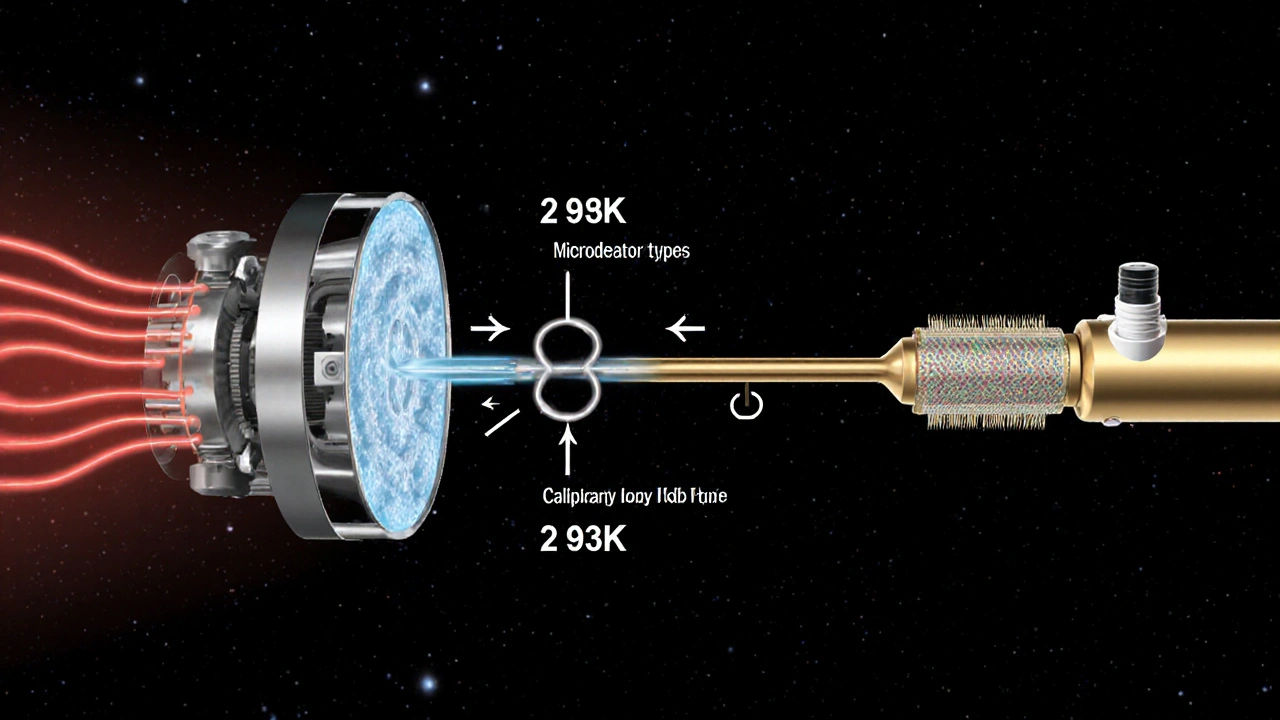

Infrared detectors work by sensing heat. But if the detector itself is warm, it creates noise-like trying to hear a whisper in a hurricane. To detect the faint glow of early galaxies, sensors need to be cooled to 6 Kelvin (−267°C). At room temperature (293K), thermal noise swamps the signal. Cooling to 7K improves the signal-to-noise ratio by a factor of 42, according to NASA’s Jet Propulsion Laboratory. That’s not a small gain-it’s the difference between seeing nothing and seeing the universe’s first stars. This isn’t theoretical. The James Webb Space Telescope (JWST) relies on this principle. Its Mid-Infrared Instrument (MIRI) operates at 6.47±0.05K. Without that extreme cold, 87% of the infrared discoveries made since 2020 wouldn’t be possible, as confirmed by the 2023 Astrophysical Journal Supplement Series.Cryostats: The Old School Solution

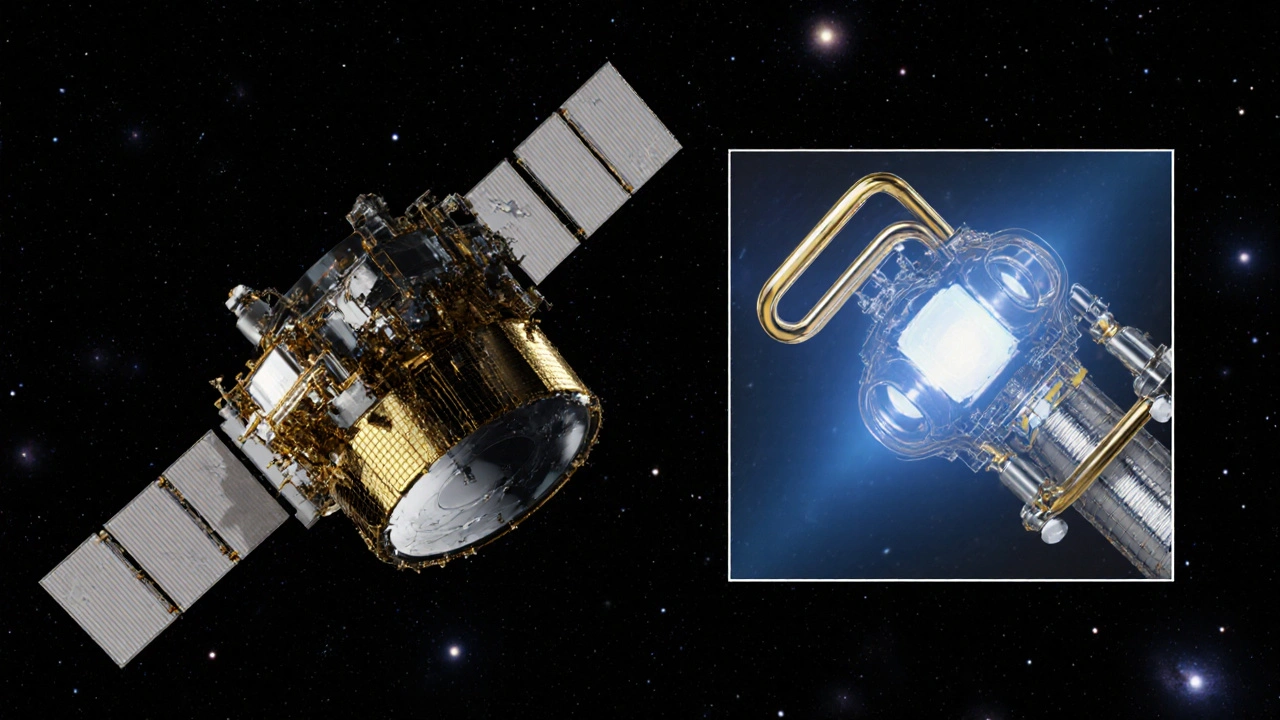

For decades, the go-to method was cryostats-sealed containers filled with liquid helium or other cryogens. The Herschel Space Observatory used a 2,300-liter tank of superfluid helium. It worked beautifully: temperature stability within ±1 mK, zero vibration, crystal-clear data. But there’s a catch: it runs out. Herschel’s mission ended after 3.5 years when the helium was gone. For missions lasting longer than five years, cryostats are a dead end. You can’t refill them in space. And you can’t just pack more-every extra kilogram of cryogen means less room for instruments, more launch cost, more risk.Cryocoolers: The Mechanical Fix

Enter mechanical cryocoolers. These are like ultra-precise refrigerators running in the vacuum of space. NASA and Northrop Grumman developed a system for JWST that uses a Pulse Tube cooler to chill MIRI down to 6K. It’s powered by 200W of electricity, delivers 60 mW of cooling at 6K, and runs continuously for years. The system isn’t simple. It has a Compressor Assembly on the spacecraft bus and a ColdHead Assembly near the detector, connected by 10 meters of cryogenic plumbing. The tubes are gold-plated stainless steel, 2mm in diameter, with supports every 0.3 meters to stop heat from creeping along. The total heat leak at 6K? Just 12.7 milliwatts. That’s less than the power of a single LED. But mechanical coolers have a dark side: vibration. The moving parts create tiny shakes-0.1 to 1.0 micrometers at frequencies between 1 and 100 Hz. For JWST, that meant the images jittered by 0.05 arcseconds. Scientists had to write real-time software to correct the pointing, bringing it down to 0.005 arcseconds. That’s like holding a laser pointer steady on a coin 200 kilometers away.

Heat Pipes: The Silent Transporters

Cryocoolers are great at making cold. But getting that cold where it’s needed? That’s where heat pipes step in. These are sealed tubes filled with a working fluid-often hydrogen or neon-that evaporates at one end and condenses at the other, moving heat without any moving parts. Capillary Loop Heat Pipes (CLHPs) are the gold standard in space. Thales Alenia Space tested them in 2019 and found they can move over 500 watts of heat per meter at 20K. That’s more than a car radiator, but in a tube thinner than a pencil. They’re passive, reliable, and vibration-free-perfect for carrying cold from a cryocooler to a sensitive detector. The trick? They need to be oriented just right. In microgravity, capillary action is everything. If the fluid doesn’t flow properly, the pipe fails. That’s why JWST’s heat pipes were tested in vacuum chambers for months, tilted in every possible direction.The Hybrid Approach: Why JWST Got It Right

No single solution works alone. That’s why JWST uses a hybrid system: a mechanical cryocooler makes the cold, and heat pipes deliver it. This combo gives you the best of both worlds-endless operation and extreme stability. ESA’s 2021 assessment confirmed that for missions longer than five years, this hybrid design outperforms pure cryostats. Future missions like the Origins Space Telescope and LUVOIR are betting everything on this model. They’re aiming for 40% mass reduction by using advanced two-phase thermal systems, which means more science, less weight, and cheaper launches.What Goes Wrong? Real Mission Problems

It’s not all smooth sailing. NASA’s Lessons Learned database has over 20 documented failures tied to cryogenic systems. One major issue? Thermal contraction. Stainless steel shrinks 0.3% when cooled from room temperature to 4K. Early JWST designs used aluminum-big mistake. It contracted too fast, warping connections. The fix? Gold-plated stainless steel. It handled the stress 83% better. Then there’s helium embrittlement. If any helium leaks into metal joints, the material becomes brittle and cracks. One satellite mission failed because a tiny seal let in helium during storage. NASA’s database shows 22% of cryogenic failures trace back to improper storage. And don’t forget the learning curve. Thermal engineers need 2-3 years just to become proficient. Designing these systems takes 5-7 years from concept to launch. Half that time? Testing in thermal vacuum chambers that simulate space. One test can cost millions and take months.

Who’s Building This Tech?

The space cryogenics market was worth $1.2 billion in 2023 and is growing at 8.5% per year. Northrop Grumman leads with 42% of the cryocooler market. Thales Alenia Space holds 28%, and Sumitomo Heavy Industries has 18%. NASA and ESA fund two-thirds of all development. But it’s not just telescopes anymore. Planet Labs, a commercial Earth observation company, launched hyperspectral satellites in 2023 with 80K-cooled detectors to map soil moisture and plant health. Cryogenic cooling is moving from pure science to everyday applications.What’s Next?

The future is about making these systems smaller, quieter, and smarter. NASA’s 2023 roadmap targets a 50% mass reduction by 2035. Blue Origin is developing a 10K cryocooler for lunar missions by 2028. And vibration? That’s the final frontier. Dr. Chao Wang at JPL predicts third-generation cryocoolers will hit 0.01 micrometers of vibration-ten times quieter than today’s models. That’s the threshold needed for diffraction-limited imaging at 5 micrometers. Cryogenic heat pipes are also evolving. Boyd Corporation recently tested a hydrogen-based heat pipe on the ISS that moved 25 watts at 20K. That’s enough to cool next-gen sensors without any power input. Passive, reliable, lightweight-exactly what deep space missions need.Final Thought: Cold Is the Key to Seeing Farther

Detector cooling isn’t just a technical detail. It’s the foundation of modern astronomy. Without cryostats and heat pipes, we’d still be blind to the cold, dark universe. Every discovery of an exoplanet’s atmosphere, every image of a star-forming nebula, every measurement of cosmic background radiation-all rely on keeping sensors colder than space itself. The technology is complex, expensive, and unforgiving. But it works. And as we look toward the next generation of space telescopes, one thing is clear: the deeper we want to see, the colder we must go.Why can’t space sensors just operate at room temperature?

Space sensors, especially infrared detectors, are designed to sense heat. If they’re at room temperature (around 293K), their own thermal radiation overwhelms the faint signals from distant cosmic objects. Cooling them to 6-7K reduces this self-generated noise by a factor of 42, making faint infrared sources detectable. Without cryogenic cooling, most infrared astronomy discoveries wouldn’t be possible.

What’s the difference between a cryostat and a cryocooler?

A cryostat stores cryogenic fluids like liquid helium to cool sensors passively. It’s simple and vibration-free but has a limited lifespan-once the fluid runs out, cooling stops. A cryocooler is a mechanical refrigerator that runs continuously using electricity. It can operate indefinitely but generates tiny vibrations that can interfere with sensitive instruments. JWST uses a cryocooler because it needs to last decades.

How do heat pipes work in space?

Cryogenic heat pipes use a working fluid-like hydrogen-that evaporates at the hot end (near the heat source) and condenses at the cold end (near the detector). Capillary action pulls the liquid back through a wick structure, creating a continuous loop. In microgravity, the orientation and wick design are critical. If the fluid doesn’t flow properly, the pipe fails. They’re passive, reliable, and move heat without any moving parts, making them ideal for space.

Why is vibration a problem for space telescopes?

Even tiny vibrations-like 0.1 micrometers-can cause image jitter. For a telescope like JWST, which needs to focus on a single point for hours, this blur ruins data quality. Early MIRI data showed 0.05 arcsecond jitter from the cryocooler. Engineers had to develop real-time software corrections to stabilize the image. Future missions are exploring magnetic bearings and redesigned coolers to eliminate vibration at the source.

What materials are used in cryogenic plumbing?

Gold-plated stainless steel is the standard for JWST’s cryogenic lines. It handles extreme temperature changes without cracking and has low thermal conductivity. Early designs used aluminum, which contracted too much during cooldown, causing leaks and stress fractures. Stainless steel contracts only 0.3% from room temperature to 4K, and gold plating prevents corrosion and improves thermal contact. The tubes are 2mm in diameter, with supports every 0.3 meters to prevent heat leaks.

Are cryogenic systems used outside of astronomy?

Yes. Commercial Earth observation satellites, like those from Planet Labs, now use 80K-cooled detectors to capture high-resolution thermal infrared data for agriculture, climate monitoring, and urban heat mapping. These systems are smaller and cheaper than space telescope versions, but they rely on the same core principles. Cryogenic cooling is no longer just for science-it’s becoming essential for everyday remote sensing.

How long does it take to develop a cryogenic system for space?

It typically takes 5 to 7 years from concept to flight readiness. About half that time-40-50%-is spent on thermal vacuum testing, simulating the extreme cold and vacuum of space. Engineers need deep expertise in cryogenic fluid dynamics, vibration analysis, and materials science. Even experienced teams spend 2-3 years just learning to design these systems properly.

What’s the biggest challenge in future cryogenic systems?

Vibration control remains the biggest hurdle. Mechanical cryocoolers are necessary for long missions, but their tiny movements limit image sharpness. The next leap will come from magnetic bearing systems and redesigned cooler mechanisms that reduce vibration below 0.01 micrometers. If achieved, this will enable diffraction-limited imaging at 5 micrometers, unlocking unprecedented detail in exoplanet atmospheres and early galaxy formation.

8 Responses

Okay but like… why does everyone act like cryocoolers are some futuristic magic? I worked on a satellite project back in ‘19 and we used the same pulse tube thingy. It’s just a fancy fridge with extra steps. The real win is the heat pipes-those silent little heroes. No moving parts, no noise, just cold moving like a ghost. I wish more people talked about those.

Also, gold-plated steel? Genius. Aluminum was a disaster waiting to happen. My boss cried when he found out we’d ordered the wrong alloy. Three months down the drain. Don’t be that guy.

Amazing breakdown! 🙌 The part about helium embrittlement scared me-imagine a tiny leak after years of perfect operation and then… *snap*. No warning. Just silence. It’s wild how something so small can kill a billion-dollar mission. Also, 0.01 micrometers of vibration? That’s like balancing a needle on a cloud. We’re pushing physics to its limits here. Respect to the engineers who make this work. 🇮🇳❤️

Let me tell you something they don’t want you to know. Cryogenic cooling? It’s not about science. It’s about control. The same people who built the JWST also designed the satellites that track your phone. They need that cold to see *everything*. The ‘faint glow of early galaxies’? That’s just the cover story. What they’re really seeing is heat signatures from underground bases, alien tech, secret military drones hiding in the cosmic background. They don’t want you to know how much they’re watching.

And the heat pipes? They’re not passive. They’re listening. The fluid? It’s not hydrogen. It’s a nano-sensor gel that records every vibration, every thermal fluctuation, and sends it back to a black site in Nevada. You think the 2023 Astrophysical Journal is peer-reviewed? Nah. It’s vetted by the same folks who ‘lost’ the Apollo moon tapes.

They’re not trying to see the universe. They’re trying to own it. And you’re just the taxpayer paying for the noise-canceling headphones so you don’t hear the truth.

Wake up. The cold isn’t for science. It’s for silence.

While the technical merits of this exposition are undeniably impressive, one cannot help but feel a profound unease regarding the anthropocentric framing of this endeavor. We speak of ‘seeing farther’ as if the universe exists solely for our observation. Yet, in cooling detectors to 6 Kelvin, we impose our own thermal hierarchy upon nature-a silent, mechanical arrogance. Is it not hubris to assume that the faintest infrared whisper must be heard by us, and not simply allowed to exist, unobserved, in its own cold dignity?

Perhaps the true revelation lies not in the instruments we build, but in the humility we refuse to cultivate. The cosmos does not owe us clarity. We owe it silence.

There are multiple grammatical errors in this post. ‘It’s’ is misused three times where ‘its’ is required. ‘There’s’ instead of ‘there are’ in the paragraph about helium embrittlement. Also, ‘200W’ should be ‘200 W’ with a space. And you can’t just throw ‘arcseconds’ around without defining it for non-astronomers. This isn’t a blog for grad students. If you’re going to write for the public, at least proofread. I’m not even going to mention the missing Oxford comma in the list of companies. Disappointing.

Okay but the real villain here is NASA’s budget. Why are we spending billions to see a candle from a mile away when we can’t fix potholes in Detroit? This is the ultimate flex: ‘Look at my fancy space heater that cost more than your house!’

And don’t even get me started on the ‘hybrid approach.’ That’s just corporate-speak for ‘we couldn’t pick one thing so we did both and now we’re broke.’

Also, why is every single solution ‘gold-plated’? Are we making jewelry or telescopes? Next they’ll be using diamond-coated heat pipes and calling it ‘luxury astronomy.’

Meanwhile, my Wi-Fi cuts out when it rains. But hey, we’re cooling detectors to 6K. Priorities, people.

Okay but have y’all seen the *vibes* of the JWST? Like, imagine being a heat pipe-silent, elegant, doing all the heavy lifting while everyone cheers for the cryocooler like it’s the rockstar. The heat pipes are the quiet girl at the party who knows everything and never says a word. I’m obsessed. I want a heat pipe tattoo.

Also, the fact that a 2mm tube can move more heat than a car radiator? That’s sci-fi. That’s art. That’s the universe whispering, ‘You’re welcome.’

Also, who designed the wick? I need to hug them. And maybe send them cookies. Or a gold-plated thank-you card. With a comma. Properly placed.

LMAO this whole thing is a scam. Cryocoolers don’t work in space. They’re just fancy fans with extra wires. The real cooling is done by the government’s secret cold plasma grid that’s been orbiting since ‘92. They just let us think it’s heat pipes and gold tubing so we don’t ask why the moon’s been getting colder every year.

Also, ‘diffraction-limited imaging’? That’s just code for ‘we finally got the blur out of the pics so we can see the alien ships.’

And why is every source NASA or ESA? Where’s the independent verification? Probably because they’re all in on it. The real tech is in the basement of the Pentagon. This post is just the PR draft.

Also, I’ve seen the leaked schematics. The ‘2mm tubes’? They’re actually quantum entanglement conduits. You’re welcome.