Imagine a satellite antenna that’s the size of a dinner plate but performs like a 2.4-meter dish. Or a spacecraft shield that doesn’t just block heat-it actively redirects it like a mirror for radiation. These aren’t science fiction. They’re real, and they’re flying in space right now, thanks to metamaterials.

What Exactly Are Metamaterials?

Metamaterials aren’t found in nature. You won’t find them in rocks, metals, or plastics. They’re built-layer by layer, structure by structure-at the nanoscale. Their power comes not from what they’re made of, but from how they’re arranged. A pattern of tiny holes, rods, or spirals can make a material bend light backward, absorb radio waves like a sponge, or push heat in one direction only. This isn’t magic. It’s physics, hacked. In the late 1990s, scientists like Sir John Pendry proved you could design materials with a negative refractive index-something nature never does. Today, those ideas are turning into hardware that’s reshaping space missions.Why Space Needs Metamaterials

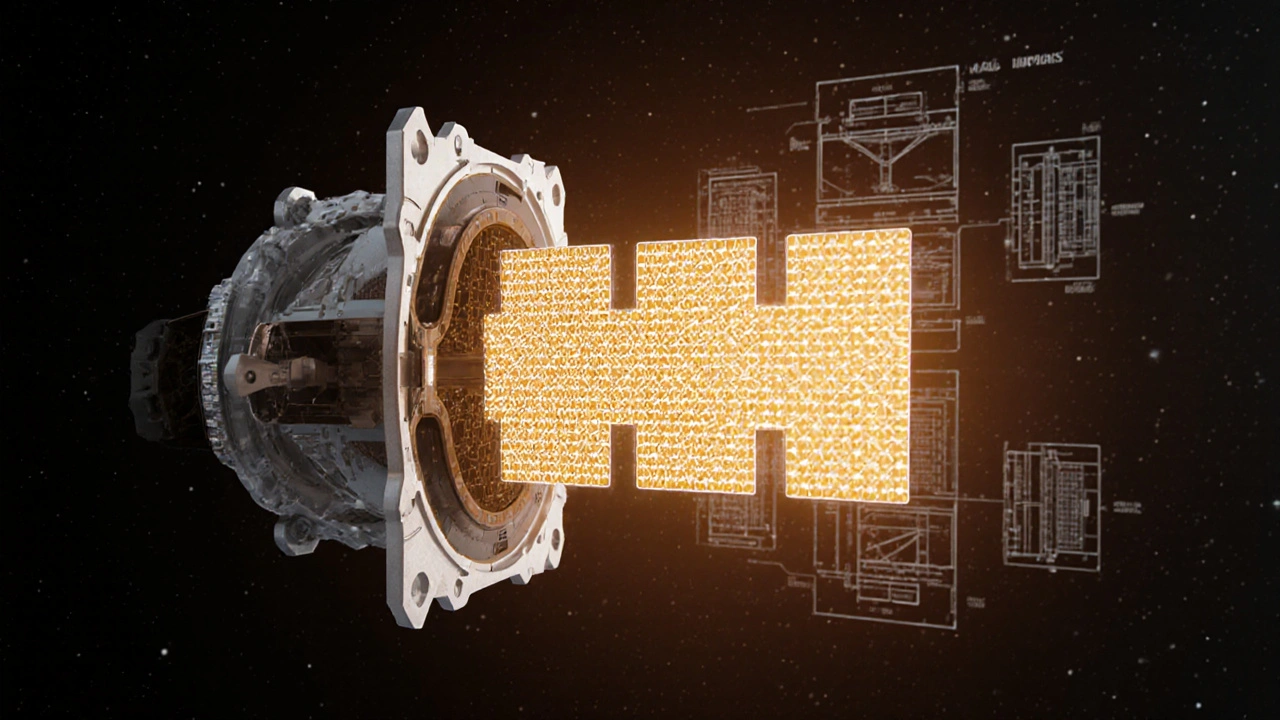

Space is brutal. Radiation fries electronics. Temperatures swing from -270°C in shadow to 150°C in sunlight. Every gram of weight costs thousands of dollars to launch. Traditional materials struggle here. Antennas are bulky. Heat shields are thick. Solar sails are heavy and inefficient. Metamaterials solve all three problems at once. Take antennas. A standard parabolic dish for deep-space communication might be 2.4 meters across. A metamaterial version? Just 15 cm by 15 cm. Kymeta’s antennas, used in Intelsat satellites, cut volume by 98.5%. That’s not a small improvement-it’s a revolution. Less mass means more room for science instruments. More bandwidth means faster data from Mars. Thermal management is another win. Conventional multi-layer insulation (MLI) reflects heat with an emissivity of 0.85-0.90. Advanced metamaterial thermal shields? They hit 0.92-0.95. That extra 5% efficiency might not sound like much, but on a mission to Europa, where every watt of heat must be perfectly controlled, it’s the difference between success and failure.Real Missions, Real Results

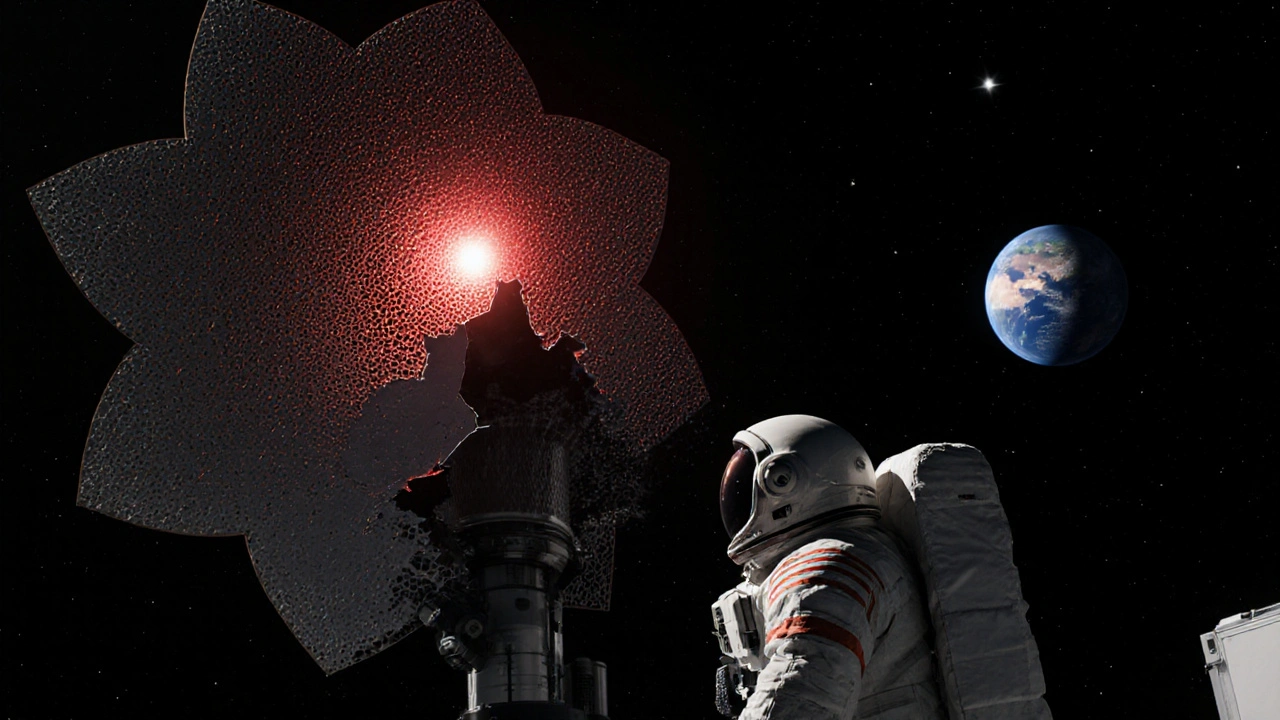

The Europa Clipper mission launched in 2024 carries a metamaterial antenna array. It’s 37% lighter than the old design. That saved space for more sensors, more cameras, more instruments to probe Jupiter’s icy moon. The Mars Sample Return mission uses a hybrid design: metamaterials for the radiating elements, traditional waveguides for feeding the signal. It’s a smart compromise-maximizing performance while avoiding the brittleness of pure metamaterials. Then there’s the starshade. A giant, flower-shaped screen meant to block starlight so telescopes can see exoplanets. NASA’s prototype, in its final design review as of March 2025, uses metamaterials to control diffraction patterns with precision no conventional material can match. Without them, the starshade would blur the light it’s trying to block. Even propulsion is changing. Solar sails made with metamaterials generate 45% more thrust per square meter than old aluminized polyimide sails. Simulations show Mars trips shrinking from nine months to five. That’s not a tweak-it’s a game-changer for human exploration.

The Hidden Costs

But it’s not all smooth sailing. Metamaterials cost 5 to 7 times more than traditional materials. A square meter of space-grade metamaterial runs around $1,850. Standard spacecraft aluminum? $250-$370. That’s a huge barrier for budget-limited missions. They’re also fragile. Micrometeoroids traveling faster than 7 km/s punch through metamaterials 32% more easily than through conventional shielding. One tiny impact can ruin a carefully engineered structure. And qualification? It takes 18-24 months to prove a metamaterial component won’t fail in space. Conventional parts? 9-12 months. That delay kills timelines for lunar missions, where every month counts. The 2023 MetOp-SG satellite had a metamaterial thermal system that failed after just 14 months in low-Earth orbit. Why? Radiation levels there exceed 300 krad/year-beyond the 100 krad limit most current metamaterials can handle. They work brilliantly in deep space. Near Earth? Not so much.Who’s Leading the Charge?

NASA and ESA are the biggest investors. Together, they fund 63% of government metamaterial R&D. Kymeta leads the market with 32% share, specializing in flat-panel antennas. Metamagnetics Inc. and Multiplas BV follow with 19% and 15% respectively. Research labs are pushing boundaries. MIT’s Portela Lab is using AI to design metamaterials in weeks instead of years. Their models predict how a structure will behave under radiation, heat, and stress before it’s even built. That could slash development time by 60% within five years. Caltech’s Harry Atwater is working on lens-less imaging systems. By using active metasurfaces that control light phase in real time, they’ve cut payload mass for space telescopes by 65%. No heavy lenses. No complex alignment. Just a thin, smart surface. And then there’s Andrea Alù at CUNY. He’s built metamaterials that break Lorentz reciprocity-meaning signals can travel one way but not the other. That’s like a one-way mirror for radio waves. It boosts signal security by 83%, making it nearly impossible for enemies to intercept or jam deep-space communications.

Where It’s Working-and Where It’s Not

Industry surveys tell a clear story. 68% of spacecraft engineers say metamaterials are essential for the next generation of missions. But 82% say qualification is the biggest roadblock. Thermal management systems? 85% success rate. Antennas? 80%. Structural metamaterials? Only 58%. That’s because bending stress and vibration are harder to model than electromagnetic behavior. A thermal shield can be tested in a vacuum chamber. A metamaterial solar panel that flexes under launch vibrations? Much trickier. The best approach? Hybrid systems. Use metamaterials where they shine-antennas, sensors, thermal control-and stick with proven metals and composites for structural parts. That’s what NASA did with Mars Sample Return. It’s not the flashiest solution, but it’s the most reliable.What’s Next?

NASA just pledged $47 million to cut manufacturing costs by 40% in three years. The goal? Get metamaterials down to 25% above conventional material prices by 2028. That’s when adoption will explode. Breakthroughs are already here. Self-healing metamaterials, developed by MIT and Lockheed Martin, can repair micrometeoroid damage up to 0.5 mm wide. 6G-compatible antennas at 140 GHz? Tested by Nokia Bell Labs and ESA. They’re efficient, compact, and ready for the next wave of deep-space comms. The future? Adaptive metamaterials. Imagine a satellite antenna that changes its frequency in real time to avoid jamming. Or a thermal shield that thickens when it senses a solar flare. AI-controlled surfaces that respond to environment, not just design. That’s the next frontier-and it’s coming fast.Final Thoughts

Metamaterials aren’t just better materials. They’re new ways of thinking about space hardware. They turn constraints into opportunities. Weight? Reduce it. Size? Shrink it. Performance? Boost it. But they demand patience, precision, and a willingness to accept higher risk for higher reward. For deep-space missions-where every gram counts and failure means losing a decade of work-they’re already indispensable. For low-Earth orbit? Still too risky. But as manufacturing improves and AI cuts design time, that will change. By 2030, 80% of deep-space missions will use them. The question isn’t if they’ll dominate. It’s how fast we can make them affordable, reliable, and ready for the next leap.What are metamaterials used for in space?

Metamaterials are used in space for antennas, thermal shielding, solar sails, and sensors. They reduce size and weight while improving performance-like replacing a 2.4-meter dish with a 15 cm panel, or boosting heat rejection by 28% compared to standard insulation.

Why are metamaterials so expensive?

They’re expensive because they require nanoscale fabrication-precision etching, layering, and alignment that can’t be done with standard manufacturing. A single square meter costs around $1,850, compared to $250-$370 for conventional materials. The process is slow, labor-intensive, and requires cleanroom facilities.

Can metamaterials survive radiation in space?

Current designs fail above 100 krad of radiation. That’s fine for deep space, where radiation is lower, but not for low-Earth orbit, where levels can exceed 300 krad/year. The 2023 MetOp-SG satellite’s metamaterial thermal system failed after 14 months because of this. Radiation-hardened versions are in development but aren’t yet flight-ready.

Are metamaterials better than traditional antennas?

Yes, in specific ways. Metamaterial antennas offer 3.2 dBi higher gain than traditional patch antennas of the same size. They’re lighter, smaller, and can be flat or conformal. But they’re more sensitive to damage and harder to qualify. Hybrid designs often work best-using metamaterials for radiating elements and traditional parts for feed systems.

How long does it take to qualify a metamaterial for space?

Typically 18 to 24 months. That’s nearly double the time needed for conventional materials. Testing includes thermal cycling, vibration, vacuum exposure, and radiation bombardment. The long timeline is one of the biggest barriers to adoption, especially for missions with tight launch windows.

Will metamaterials be used on crewed missions?

Absolutely. NASA’s Artemis program and future Mars missions will rely on them for lightweight communication systems, compact power sensors, and adaptive thermal control. Crewed missions need every gram saved and every watt optimized-metamaterials deliver that. The first crewed mission using them is expected by 2030.

What’s the biggest challenge with metamaterials today?

The biggest challenge is the long, expensive qualification process. Even with perfect design, getting a metamaterial approved for space takes years. Manufacturing is complex, testing is exhaustive, and failure rates are higher than conventional parts. Until costs drop and timelines shrink, adoption will be limited to high-value missions.

15 Responses

so like... these things are basically magic foil? i heard they make antennas tiny but also break if you look at them wrong. kinda wild.

Metamaterials aren't revolutionary-they're overhyped. The real issue is the 24-month qualification cycle. If you can't deploy it before your funding expires, it doesn't exist. This isn't science-it's bureaucratic theater with a nanoscale veneer.

why are we spending millions on space glitter when we can't fix the power grid? this is like putting a diamond on a paperclip and calling it innovation.

Let me tell you something about metamaterials-this isn’t just about shrinking antennas or boosting thermal efficiency. It’s about rethinking how we even define materials in the first place. We’ve spent centuries thinking of materials as static substances-aluminum, titanium, composites-and now we’re learning that structure is the real ingredient. A pattern of nanoscale spirals can bend electromagnetic waves like water around a rock, and that changes everything. Think about it: we’re no longer limited by what nature gives us. We’re becoming architects of physical law. That’s not engineering-it’s alchemy with math. And yes, the cost is insane. A square meter of this stuff costs more than a used motorcycle. But when you’re launching a probe to Europa, and every gram saved means another sensor, another camera, another chance to see what no human has ever seen, does it really matter? The MetOp-SG failure? That’s not a reason to quit. That’s a lesson. Radiation tolerance isn’t a feature-it’s a design constraint we haven’t fully cracked yet. And yeah, qualification takes two years. But MIT’s AI models are cutting that down. Imagine designing a metamaterial in a week and simulating its behavior under 300 krad of radiation before you print a single layer. That’s the future. Hybrid systems are the smart bridge-use metamaterials where they dominate, stick with aluminum where you need durability. This isn’t about replacing everything. It’s about augmenting everything. And when we do? We’ll look back at the old parabolic dishes like we look at vacuum tubes. And the starshade? That’s not just a shield. It’s a telescope’s new lens. No glass. No weight. Just light controlled by geometry. That’s poetry in physics.

How quaint. You treat metamaterials like they’re the pinnacle of human ingenuity. The truth? They’re just another overpriced, fragile novelty that only works in the vacuum of academic papers. NASA’s ‘breakthroughs’ are just incremental tweaks dressed up as revolutions. And don’t get me started on that ‘self-healing’ nonsense-it’s a lab curiosity that’ll fail under real micrometeoroid bombardment. The real innovation? Still waiting. The rest is PR.

I think it’s important to recognize that metamaterials aren’t perfect-but they’re a step forward. The fact that we’re even talking about bending light or redirecting heat with engineered structures is incredible. Yes, they’re expensive and fragile. But so were transistors in the 1950s. We don’t give up on tech just because it’s hard. We keep improving it. The hybrid approach NASA’s using? That’s actually brilliant. It’s not about choosing between old and new-it’s about blending them wisely. And if AI can cut design time in half? That’s huge. We’re not just building better satellites-we’re learning how to build smarter systems. That’s the real win.

What does it mean to engineer reality? We used to think of matter as fixed-gold is gold, silicon is silicon. Now we’re learning that form is the true substance. A metamaterial doesn’t change what atoms are present-it changes how those atoms speak to each other. It’s not about composition. It’s about conversation. And in space, where silence is deadly and every photon matters, this conversation is the difference between seeing Europa’s ocean… and never knowing it was there. We’re not just building hardware. We’re tuning the universe’s frequency. And maybe, just maybe, that’s the first step toward listening to something we’ve never heard before.

It’s amazing how far we’ve come. These materials are still rough around the edges, but the potential is undeniable. Every mission that uses them brings us closer to exploring deeper, farther, faster. Keep pushing. The future is listening.

Let’s cut the fluff. Metamaterials work great in deep space but die in LEO. The 2023 MetOp-SG failure proves it. We’re not ready for them in low orbit. Stop pretending. Fix the radiation tolerance first. Then we’ll talk.

Oh wow another space fairy tale. $1850 for a square meter of space glitter? And you call that progress? We’re spending more on this than on actual human needs. And the fact that it breaks if a dust particle hits it? That’s not innovation. That’s a liability with a PhD.

Look, I get it-you’re excited. But let’s be real: if a material can’t survive 300 krad/year without crumbling, it’s not a breakthrough, it’s a time bomb. And the 24-month qualification? That’s not ‘due diligence,’ that’s a bureaucratic chokehold. And don’t even get me started on the ‘hybrid’ approach-sounds like a compromise for people who don’t want to admit they picked the wrong horse. Also, ‘self-healing’? In space? With micrometeoroids moving at 7 km/s? That’s like saying your car’s paint can heal after a truck hits it. You’re not engineering. You’re wishful thinking.

The structural limitations of metamaterials under vibrational stress remain underreported. While electromagnetic performance is well-documented, mechanical resilience in launch environments lacks sufficient empirical validation. This represents a critical gap in mission assurance protocols. Further study is required.

In India, we call this ‘jugaad’-making magic from scraps. These materials are the same. Smart. Cheap in the long run. Just need time.

It’s not about whether metamaterials are better. It’s about whether we’re ready to accept that progress isn’t always safe. We used to say the same about satellites, about solar panels, about ion thrusters. Every leap feels risky until it becomes routine. The real question isn’t ‘can they survive?’-it’s ‘are we brave enough to let them fly?’

USA leads. China is trying to copy. Europe is slow. Russia? They’re still using 1980s tech. Metamaterials are American innovation. We built it. We own it. And we’re not sharing.